Ultimate Guide to Swiss Cheese Model and Its Applications

With over two decades in business – spanning strategy consulting, tech startups, and executive leadership – I am committed to helping your organization thrive.

At Reliability, we’re on a mission to help enhance strategic decision-making and operational excellence through the power of Root Cause Analysis, and I hope this article will be helpful!

Our goal is to help you better understand root cause analysis by offering insights and practical tips based on years of experience. Whether you’re new to doing RCAs or a seasoned pro, we trust this will be useful in your journey towards working hard and working smart.

———————

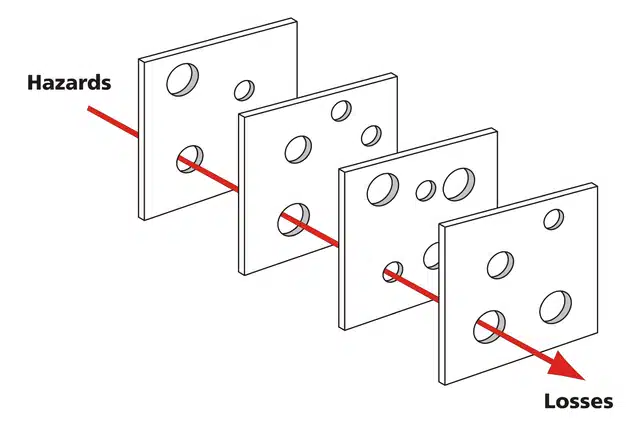

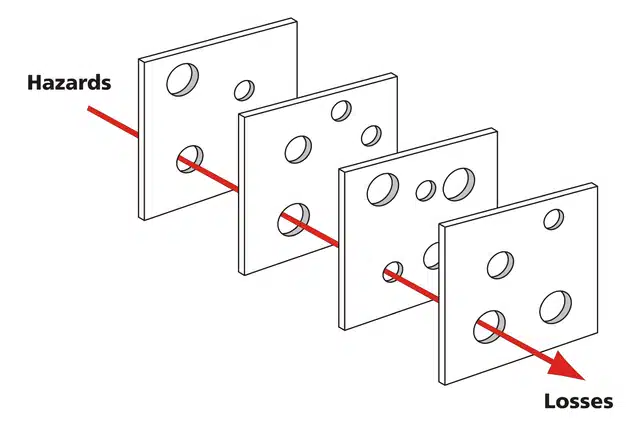

The Swiss Cheese Model is a term used to describe risk management and human error in complex systems. This metaphor is commonly applied in healthcare, aviation, engineering and other fields to demonstrate that if they have to pass through numerous defenses (each represented by a slice of cheese), errors can be prevented.

These layers contain gaps which represent points of weakness or vulnerability — so what should be done is to establish the necessary arrangement in such a way as there are no two sets of hole areas which overlap thereby creating a continuous line for failure propagation.

One of our earlier article showed a different view to Swiss Cheese Model. In this post we will discuss what the Swiss cheese model means, where it can be used and why every safety plan or risk management strategy needs it.

What is the Swiss Cheese Model?

Developed by James Reason as a tool for preventing risks and errors in the 1990s, the Swiss Cheese Model is now one of the most basic concepts on which safety rests within various domains including healthcare aviation and engineering. As stated, many defenses ought to work together even though each might have some weaknesses because then they will prevent catastrophes from occurring.

The brilliance behind this lies with recognizing that all protective measures are fallible individually; but when combined successively with other levels they enhance system-wide safety greatly. This becomes very handy in areas where small missteps may lead to great failures hence require tight control over possibilities of making mistakes.

As an example, think about different pieces of Swiss cheese put side by side with irregular gaps. Patterns can be discerned between layers therefore some weak points are compensated for by stronger ones found within another sheet thereby reducing risks.

How the Model Works

If you were to place several slices of Swiss cheese next to each other wherein there are random holes scattered throughout, you would get something resembling the Swiss Cheese Model visually.

These perforations represent single layer defense vulnerabilities such as human errors or security protocol breaches. But what makes these perforated sheets effective is their positioning relative to one another. Since the gaps are distributed in an unsystematic manner, it follows that typically a solid portion from one slice will cover up for the gap on another.

This arrangement therefore significantly minimizes opportunities through which threats or errors can pass undetected across multiple levels. Simply put, it is a diagrammatic representation that helps us understand how various safety nets overlap so as to catch and stop mistakes before they turn into disasters.

Redundancy within critical systems is emphasized by this model where even if one fails there should still be other backups providing necessary protection against risks.

Applications of Swiss Cheese Model Across Industries

Healthcare

In healthcare, nothing is more important than patient safety. The Swiss cheese model provides an excellent foundation for improving it. Every aspect of patient care, from prescribing medication to carrying out medical procedures can be thought of as a slice of cheese.

Through this model, providers can identify where they are weak at each step in the process so that they may tighten those areas up and lessen their chances of making errors which could hurt patients. For instance, multiple checks on patient identification with medication dosage calculation along surgical procedure planning ensure detection and correction of mistakes made at one point from another thus guarding against what happens to a patient.

Aviation

The aviation industry relies heavily on the Swiss cheese model because failures have such severe consequences. Pilot training has to be rigorous, aircraft maintenance needs thoroughness while air traffic control operations should be careful if we want critical safety layers in aviation to exist.

According to this model, every layer is like a slice of cheese that helps cover possible holes that may lead into accidents. Therefore, these layers are probed one after another systematically – checking until balance among them is attained since any slackness on one part will always be picked at by subsequent parts thereby keeping record safe with crew’s lives being also protected.

Engineering

The world today has safety-critical fields such as nuclear or chemical engineering which put great emphasis on safety more than anything else anywhere else in the world today. Swiss Cheese Model offers real-world rather than just theoretical fail-safe design against human and mechanical errors within these domains since it serves better here when employed meticulously compared to being only used as a conceptual framework somewhere else.

Many people do not know but there must always be several levels for prevention whenever this occurs therefore even if any single level fails then others shall come into play so as to prevent disaster stepwise carefully without leaving out anything. Even now were it not for such models we would still experience bigger frequent accidents internationally and nationally.

Benefits of the Swiss Cheese Model

Enhanced Safety

One more point that has made the Swiss Cheese Model so popular is its ability to enhance safety significantly. This involves identifying weaknesses in each safety measure, which then becomes the basis for requiring several layers of defense to overlap.

In doing so, it greatly reduces the likelihood of any single failure point causing a complete system failure. What does this mean practically? It means there will be many more protections built into working systems themselves and also individuals who depend on them, hence becoming widely adopted in industries where safety cannot be taken lightly.

Improved Error Management

The Swiss Cheese Model is very good at realizing error dynamics in complex systems. It promotes safety before accidents by recommending different preventive measures that should also be duplicated.

When organizations take up such a model, they develop stronger ways of identifying errors and correcting them which leads to a significant decrease in both the probability and impact of errors. This systematic approach to mistake management prevents failures while fostering reliable structures for operational activities.

Fosters a Culture of Continuous Improvement

The Swiss cheese model’s greatest strength lies in its ability to foster a culture of continuous improvement among organizations. Teams would use this model for failure analysis as a way to keep refining their safety procedures over time.

Such an ongoing process prepares establishments for potential threats thereby making them proactive and responsive to new challenges which ensures that defenses remain strong throughout while maintaining secure operations always.

One of the proactive approaches to continuous improvement is the PROACT® method. The PROACT® method supports operational excellence by promoting a culture of continuous improvement. By identifying and addressing root causes, organizations can prevent recurring issues, improve efficiency, and enhance performance. This proactive approach to problem-solving encourages a mindset of prevention rather than reaction, fostering a culture that values quality, safety, and efficiency.

Limitations of the Swiss Cheese Model

As good as the Swiss cheese model may look, it does come with its own share of flaws. Critics say that it simplifies too much for complex systems like modern ones which are highly dynamic and interconnected. In other words, this model fails to capture these aspects adequately.

They point out that sometimes it only shows some paths through which errors can travel in an organization or industry with many parts that depend on each other, yet there could be more routes along which mistakes might move through such a system.

Despite the shortcomings, critics still know very well also that such models are able to serve as useful starting points for safety management improvement.

Real-World Examples of the Model in Action

Aviation Incident Analysis

Every day in the aviation sector where peoples’ lives are at stake accidents become a great worry since they pose a danger to human life. The Swiss cheese model is used extensively as an accident investigation tool within this field because prevention measures must be strong due to the high risks involved.

After an unfortunate event happens, investigators trace failures across multiple layers of protection until slices line up like cheese during their analysis revealing weaknesses in airline systems through which hazards can enter if appropriate actions were not taken earlier enough thereby prompting relevant authorities’ intervention before another similar incident occurs.

Healthcare Quality Assurance

The significance of the Swiss Cheese Model cannot be overemphasized when it comes to quality control assurance processes in hospitals and any other health care setting worldwide. Healthcare facilities need to be places where a patient’s safety is guaranteed because everyone would expect to leave there feeling better than when they came seeking medical attention.

Healthcare providers use the Swiss Cheese Model during investigations into adverse events to determine where errors occurred while delivering care to individuals with diverse needs. Staff responsible for patient welfare and managing equipment functions, among other tasks, use this model to identify weaknesses when addressing health issues.

Through doing such, areas where breakdown in communication might have occurred leading to failure to communicate among them will be identified which would enable correction of such situations earlier before−hand if necessary for effective provision of care services to patients.

Incorporating the Swiss Cheese Model in Daily Operations

Risk Assessment

The Swiss cheese model can be used in daily operations of many businesses especially during risk evaluation stages. It requires them to view their systems and processes as Swiss Cheese layers so that they can identify points of failure, institute necessary controls and make sure there is overlap among the controls.

These measures enable firms to deal with weaknesses in their activities before they are discovered through errors or failures. For instance, weak areas along production lines should be identified and strengthened against costly defects which might necessitate product recalls, thereby safeguarding both reputation and bottom line of manufacturing enterprises.

Training and Awareness

One approach for building resilience into an organization is by ensuring everyone understands the Swiss Cheese Model. In order to create a culture where risks are managed proactively through constant vigilance it would be best if establishments trained widely on principles underpinning this model as well as its various applications.

Workers who know how safety nets can be layered will not only be able to see potential failure points earlier than others, but also handle them appropriately before they escalate into serious problems. For example, staff members armed with knowledge about Swiss Cheese Model may notice abnormal behaviors indicative of hacking attacks, thus helping prevent compromise of sensitive data or computer network breaches.

Conclusion

This is said to be one of the simplest, yet most effective methodologies across all sectors worldwide – since no other error prevention technique has achieved such universal success like the Swiss Cheese Model. It greatly enhances safety levels in any system from the aviation industry up to healthcare, among many other sectors.

It significantly increases overall system resilience through compensatory layering. Hence, if any business wants higher standards of safety coupled with reduced hazards, then it must adopt this strategic view on weaknesses together with promoting continuous improvement through vigilance.

__________

I hope you found this guide to Swiss Cheese model insightful and actionable! Stay tuned for more thought-provoking articles as we continue to share our knowledge. Success is rooted in a thorough understanding and consistent application, and we hope this article was a step in unlocking the full potential of Root Cause Analysis for your organization.

Reliability runs initiatives such as an online learning center focused on the proprietary PROACT® RCA methodology and EasyRCA.com software. For additional resources, visit Reliability Resources.

Recent Posts

How to Improve Your RCA Program: A Practical Guide for Reliability Leaders

The 2026 Reliability Cost Curve: How World-Class Teams Bend It Downward

The Reliability Leader’s 2026 RCA Playbook: A Straightforward Guide to Starting the Year Strong

Why You Never Have Time for Root Cause Analysis (And How World-Class Teams Fix It)

Root Cause Analysis Software

Our RCA software mobilizes your team to complete standardized RCA’s while giving you the enterprise-wide data you need to increase asset performance and keep your team safe.

Root Cause Analysis Training