How to Use PROACT® for Root Cause Analysis: A Structured Approach to Problem Solving

- What Does PROACT® Stand For?

- Step 1: Preserving Evidence and Acquiring Data

- Step 2: Order Your Analysis Team and Assign Resources

- Step 3: Analyze the Event

- Step 4: Communicate Findings and Recommendations

- Step 5: Track and Measure Impact for Bottom-Line Results

- How EasyRCA Perfectly Supports the PROACT® Methodology

- Frequently Asked Questions

- How EasyRCA Enhances PROACT® Analysis

- Bringing PROACT® to Life with EasyRCA

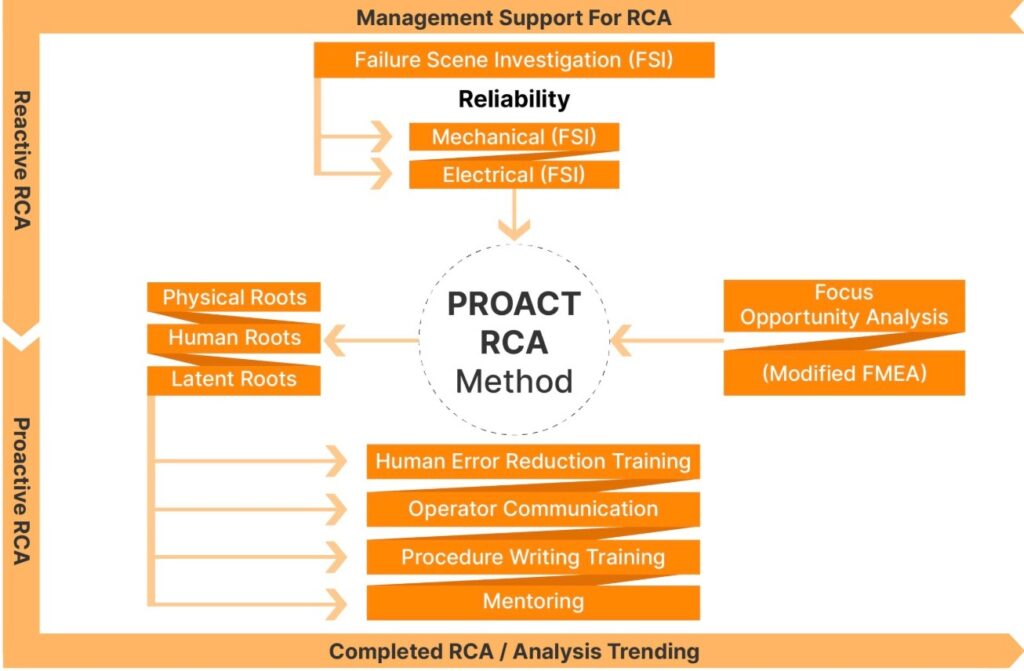

PROACT® is one of the most recognized and proven methodologies in the reliability and root cause analysis (RCA) world. Developed by Reliability Center, Inc., the PROACT® approach provides a structured, repeatable, and evidence-based process that enables teams to solve problems systematically and prevent recurrence.

Unlike ad hoc problem-solving or reactive firefighting, PROACT® emphasizes discipline—collecting facts before jumping to conclusions, building cross-functional teams, and using logic-based reasoning to uncover true root causes. This makes it a cornerstone among modern Root Cause Analysis tools and a key methodology taught in professional RCA training worldwide.

In this guide, we’ll explore what PROACT® stands for, detail its five steps, share real-world applications, and explain how EasyRCA can support PROACT® workflows to ensure consistency, collaboration, and measurable reliability.

What Does PROACT® Stand For?

The PROACT® acronym defines a disciplined, step-by-step approach to problem-solving:

- Pr – Preserve Evidence and Acquire Data

- O – Order Your Analysis Team and Assign Resources

- A – Analyze the Event

- C – Communicate Findings and Recommendations

- T – Track and Measure Impact for Bottom-Line Results

Each stage builds on the previous one, ensuring that investigations are factual, unbiased, and actionable. Let’s walk through each phase in detail.

Step 1: Preserving Evidence and Acquiring Data

Every great investigation starts at the scene. In PROACT®, this first step emphasizes preserving evidence and gathering data in a disciplined way—similar to how investigators approach a crime scene.

The 5-Ps of Data Collection

To simplify data gathering, PROACT® categorizes evidence into five data dimensions, known as the 5-Ps:

- Parts: Physical components involved in the failure.

- Position: Environmental or system location of the event.

- People: Personnel involved—operators, technicians, decision-makers.

- Paper: Documentation such as maintenance logs, work orders, and procedures.

- Paradigms: Cultural or systemic factors influencing how work is done.

Goal: Establish a clear, fact-based foundation for analysis before making assumptions.

Step 2: Order Your Analysis Team and Assign Resources

A successful RCA depends on the right people. In PROACT®, this step is about building an unbiased, multidisciplinary team to evaluate the event.

Key Actions:

- Select team members with technical knowledge, process expertise, and operational insight.

- Define clear roles—facilitator, evidence gatherer, data analyst, and decision owner.

- Ensure neutrality by avoiding individuals directly responsible for the event outcome.

Why It Matters: The quality of your conclusions depends on the diversity and objectivity of your analysis team.

Step 3: Analyze the Event

This is the analytical core of the PROACT® methodology—the moment when data becomes insight. After evidence is preserved and the team assembled, analysis transforms information into understanding by connecting what happened, how it happened, and why it happened.

In PROACT®, this step focuses on structured logic and validation rather than speculation. The team systematically reconstructs the sequence of events, examines failure pathways, and tests hypotheses against real evidence. The outcome is a defensible, evidence-based understanding of cause and effect.

PROACT® emphasizes the use of logic trees to map cause-and-effect relationships visually and rigorously. Each branch represents a potential causal pathway that must be either validated or disproven. This disciplined process prevents bias, eliminates guesswork, and ensures that no possible contributor—physical, human, or systemic—is overlooked.

Step 4: Communicate Findings and Recommendations

Half of the RCA effort lies in communication. Once root causes are validated, the team must translate findings into clear, actionable recommendations.

Best Practices for PROACT® Communication:

- Document evidence: Include visuals and logic tree summaries.

- Align with leadership: Present causes and corrective actions linked to business goals.

- Prioritize actions: Address high-risk or recurring issues first.

- Follow through: Assign owners and set implementation timelines.

Without clear communication and accountability, even the best analysis can fail to drive change. EasyRCA automates report generation, making it simple to share findings with executives, regulators, and cross-functional teams.

Step 5: Track and Measure Impact for Bottom-Line Results

Completing an RCA doesn’t end with recommendations—it continues through validation and measurement.

PROACT® requires tracking implemented actions to confirm they’re effective and delivering measurable benefits. Each corrective action should have a performance metric tied to it—such as reduced downtime, fewer quality defects, or improved safety compliance.

Example Metrics:

- Percentage reduction in repeat incidents.

- Maintenance cost savings.

- Increased asset uptime or mean time between failures (MTBF).

- Positive ROI demonstrated on corporate dashboards.

By tracking these outcomes, organizations close the loop on reliability improvement and prove the tangible value of structured RCA.

How EasyRCA Perfectly Supports the PROACT® Methodology

With EasyRCA, we understand that applying the PROACT® methodology is essential for effective root cause analysis and long-term reliability improvements. With our intuitive platform, AI assistance, and seamless integration, EasyRCA helps teams implement the PROACT® methodology efficiently, streamlining problem-solving and ensuring your actions are always data-driven and focused on results.

Key PROACT® Steps with EasyRCA:

- Pr: Preserving Evidence and Acquiring Data

EasyRCA automatically collects critical data and incident details, ensuring that no important information is missed during the RCA process. With real-time collaboration, every team member has access to the latest data as the investigation unfolds. - O: Order Your Analysis Team and Assign Resources

EasyRCA simplifies team collaboration by allowing multiple users to contribute to the investigation simultaneously. Whether you’re working with a small team or coordinating across multiple departments, the platform ensures that everyone is aligned and working toward the same solution. - A: Analyze the Event

With EasyRCA’s intuitive logic tree and Fishbone diagram methods, you can quickly visualize potential causes and narrow down the root causes through AI-assisted suggestions. The 5 Whys and other RCA methods are seamlessly integrated into the platform, ensuring that the analysis is thorough and precise. - C: Communicate Findings and Recommendations

EasyRCA makes it easy to share your findings with stakeholders. The automated report generation feature ensures that your RCA results are formatted and ready for sharing, with actionable recommendations that align with PROACT®’s best practices. - T: Track and Measure Impact for Bottom Line Results

EasyRCA’s centralized task assignment allows you to track the implementation of corrective actions over time, measure their effectiveness, and verify long-term improvements. By monitoring the impact of changes, you can ensure continuous improvement and sustainability in your processes.

Frequently Asked Questions

What makes PROACT® different from other Root Cause Analysis Methods?

Unlike generic RCA methods, PROACT® integrates both physical and human factors within a single, evidence-based framework. It’s designed to be systematic, repeatable, and results-driven.

Can PROACT® be used with digital RCA tools?

Absolutely. EasyRCA complements the PROACT® methodology perfectly, providing digital logic trees, real-time collaboration, and consistent reporting that align with PROACT® principles.

Is PROACT® suitable for all industries?

Yes. Whether you’re managing manufacturing assets, medical systems, or administrative processes, PROACT® adapts to any environment where cause-and-effect understanding leads to improvement.

How EasyRCA Enhances PROACT® Analysis

EasyRCA supports every stage of the PROACT® analysis process. The platform includes:

- Interactive logic trees for structured analysis.

- AI-assisted insights to help identify patterns or recurring contributors.

- Evidence attachments for traceable decision-making.

- Real-time collaboration for multi-site teams.

- Automated reporting to communicate results clearly and quickly.

These capabilities make EasyRCA the perfect digital companion to the PROACT® methodology, helping teams maintain consistency, transparency, and speed across investigations.

Bringing PROACT® to Life with EasyRCA

The PROACT® methodology transforms problem-solving into a disciplined, data-driven process. By preserving evidence, assembling the right team, analyzing events with logic, communicating effectively, and tracking results, organizations can reduce risk, optimize costs, and enhance long-term reliability.

Pairing PROACT® with digital Root Cause Analysis tools like EasyRCA helps teams apply these principles consistently, turning every investigation into measurable business value.

If you’re ready to move from understanding PROACT® to applying it efficiently, explore how EasyRCA can support your organization’s reliability goals.

👉 Enroll in the PROACT® RCA Methodology and Certification (RCA 301) course or contact our team about bring in depth RCA training to your organization.

👉 Visit EasyRCA to request a demo, download a free RCA template, or start your trial today.

Recent Posts

How to Use PROACT® for Root Cause Analysis: A Structured Approach to Problem Solving

5 Whys Root Cause Analysis vs. Logic Trees: Which One Works Best?

Root Cause Analysis Example: From Incident to Insight in 5 Steps

How Root Cause Analysis Training Builds a Culture of Reliability

Root Cause Analysis Software

Our RCA software mobilizes your team to complete standardized RCA’s while giving you the enterprise-wide data you need to increase asset performance and keep your team safe.

Root Cause Analysis Training