Recognizing Basic Gear Fatigue Failure Patterns

What are Fatigue Failure Patterns?

- Fatigue occurs when a material is subjected to repeated loading and unloading.

- When the loads are above a certain threshold, microscopic cracks will begin to form at a material’s surface.

- Cracks always begin in highly stressed areas of a material.

- Eventually, a crack will reach a critical size, and the structure will suddenly fracture.

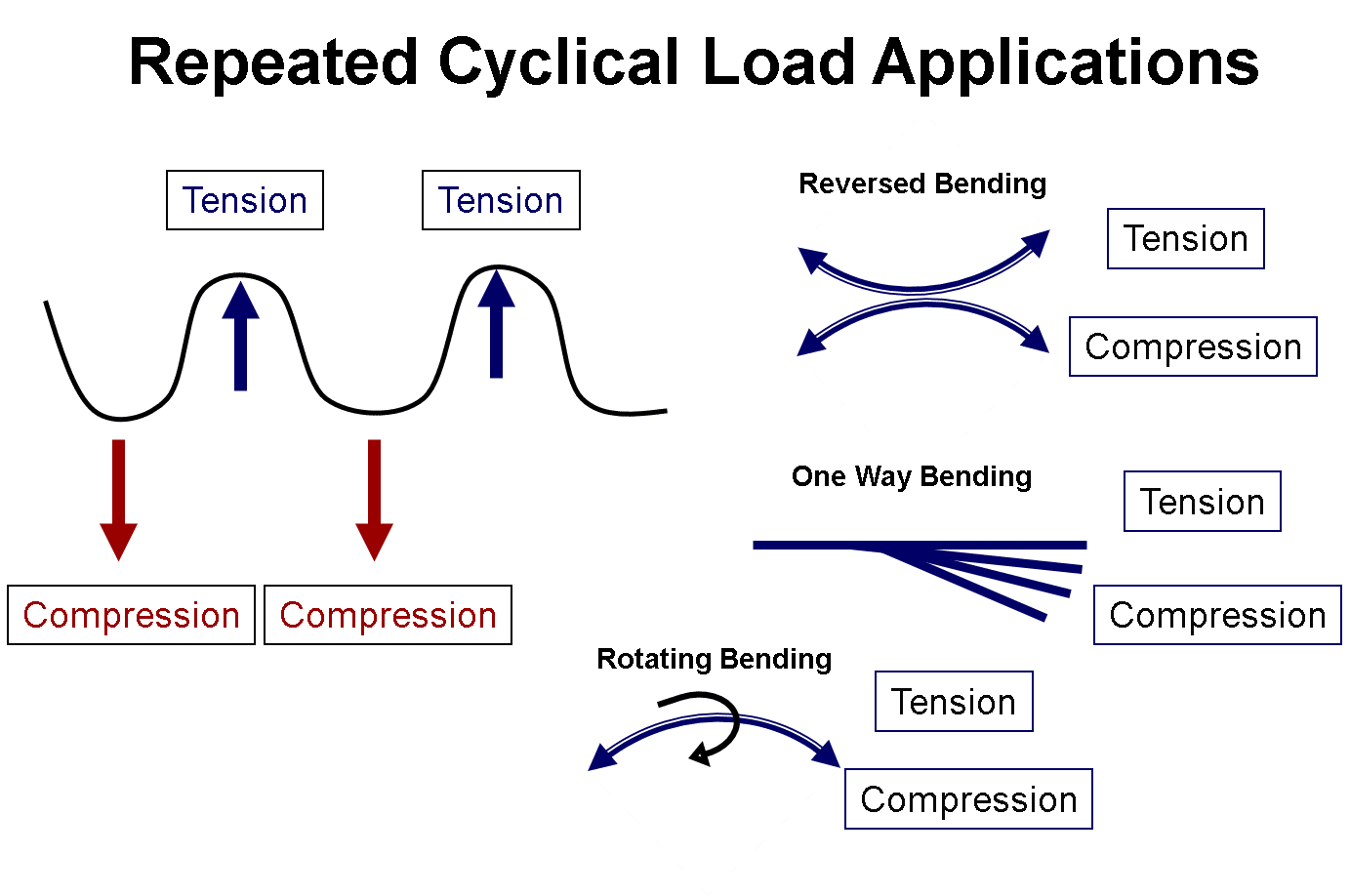

In our prior blog on Fatigue we discussed the various cyclical loading applications. Let’s review them again with this graphic.

Basic Characteristics of Gear Fatigue

Now let’s get a little bit more specific and discuss the basic characteristics of Gear fatigue. Some of these basics are:

- They always have an origin(s)

- Progression marks may be visually present (depending on load variations)

- They will have a Final Fracture Zone (FFZ)

- Ratchet marks may be present

- Spalls (or Hertzian Fatigue), may be present

- Electrical fluting may be present

- Evidence of inadequate lubrication may be present

Let’s run through some failed parts and see if we can associate these characteristics to them.

(1) This gear is heavily damaged at the addendum or top. The origin is Hertzian (beneath the surface working outward). Once the wear is through the case-hardened area, the failure will be rapid.

(2) This crack was initiated in the gear root and was under normal loads.

(3) The crack was initiated in the gear root and was under heavy loads because of the large FFZ.

(4) The crack was initiated in the gear root where the stresses are high.

(5) This gear is damaged at the addendum or top. The origin is Hertzian (beneath the surface working outward). This defect is often a result of misalignment.

(6) This gear is also damaged at the addendum or top. The origin is Hertzian (beneath the surface working outward). This defect is often a result of misalignment.

Just as an FYI, I am pulling all of this material from our public workshops as usual. These workshops appeal to the novice as well as the more seasoned investigators who just want to learn more about the physics of failure, recognizing common failure patterns and understanding how those patterns came to form.

Please click the hyperlink if you’re interested in more job aides likes this and/or information on associated training and tools to help with understanding Why Parts Fail.

As always, I appreciate all of the great feedback and sharing from the veterans in the field, and equally as important, the front-lines who make things happen!! Thank you for your time and participation.

About the Author

Robert (Bob) J. Latino is former CEO of Reliability Center, Inc. a company that helps teams and companies do RCAs with excellence. Bob has been facilitating RCA and FMEA analyses with his clientele around the world for over 35 years and has taught over 10,000 students in the PROACT® methodology.

Bob is co-author of numerous articles and has led seminars and workshops on FMEA, Opportunity Analysis and RCA, as well as co-designer of the award winning PROACT® Investigation Management Software solution. He has authored or co-authored six (6) books related to RCA and Reliability in both manufacturing and in healthcare and is a frequent speaker on the topic at domestic and international trade conferences.

Bob has applied the PROACT® methodology to a diverse set of problems and industries, including a published paper in the field of Counter Terrorism entitled, “The Application of PROACT® RCA to Terrorism/Counter Terrorism Related Events.”

Recent Posts

How to Improve Your RCA Program: A Practical Guide for Reliability Leaders

The 2026 Reliability Cost Curve: How World-Class Teams Bend It Downward

The Reliability Leader’s 2026 RCA Playbook: A Straightforward Guide to Starting the Year Strong

Why You Never Have Time for Root Cause Analysis (And How World-Class Teams Fix It)

Root Cause Analysis Software

Our RCA software mobilizes your team to complete standardized RCA’s while giving you the enterprise-wide data you need to increase asset performance and keep your team safe.

Root Cause Analysis Training