A Beginners Guide To Root Cause Analysis (RCA) 2025

Reading Time: 4 minutes

When issues arise within a company, there are a number of ways to problem solve. Root Cause Analysis (RCA) is an effective method to identify and solve problems in business by determining the underlying inefficiencies or imperfections and taking the necessary steps to address them to prevent the problem from arising again. Root Cause Analysis (RCA) can be an effective

Top 5 Keys to a Proactive RCA Culture Shift…

Reading Time: 4 minutes

RCA’s are traditionally viewed as ‘hindsight’ (reactive) analysis… But what about the chronic failures (that happen daily), the near-misses and the unacceptable risks (identified using risk tools like FMEA)? Left unchecked, these types of events often lead to one-time sporadic failures (the triggered ones). How to Create a Proactive RCA Culture From a holistic RCA perspective… “What are the top

Reliability Certified Affiliate Program

Reading Time: 2 minutes

In order to maximize the impact and objectives of Reliability Center Inc. worldwide, we are now publicly offering our Affiliate Program to new applicants! Our PROACT methodology provides a balanced step-by-step method to teach and train your clients how to maximize the ROI of their RCAs. Paired with our courses, consulting, and various software offerings – the potential for impact

The Anatomy of a ‘Failure’

Reading Time: 5 minutes

Where does ‘failure’ come from? Why do some things not go as we planned? When bad things happen, at that time, it can be chaotic and appear very complex. Often, in hindsight (when the urgency has faded), we find that good people made bad decisions at that time. Most of the time such failures were not complicated and we find

EasyRCA Continues To Grow Its Features, Customer Base, & Strategic Partnerships.

Reading Time: < 1 minute

Our newest software offering, EasyRCA, continues to grow with both an increasing user base as well as with strategic partnerships. One example is a partnership agreement announced this week with Uptake. Through this non-exclusive partnership, EasyRCA has once again validated itself as a powerful solution for helping Reliability Teams increase their ROI while completing better, faster RCAs. “Joining RCI’s root

RCA Principal Analysts vs Subject Matter Experts: What’s the Difference?

Reading Time: 11 minutes

Abstract: An undesirable event occurs (fancy term for unexpected failure) a Root Cause Analysis (RCA) is triggered. This usually means what occurred is a severe event as triggers are often set pretty high (i.e. – reportable injury/fatality, equipment damage in excess of >$$k, production losses in excess of > $$k, regulatory violation, etc.). Since there is urgency and visibility, how

‘Facebook’ Maintenance & Reliability: The Illusion of Performance

Reading Time: 10 minutes

Abstract: I used to be on Facebook many years ago in an effort to keep up with old friends. However, I began to realize the forum was often used to create an illusion that someone wanted their community to have about them. I knew many of these people creating such illusions, that is how I know they were ‘illusions’. Their

Chronic Failures: Treasures in Plain Sight

Reading Time: 6 minutes

Chronic Failures = Hidden Treasures When we look at the widely used and misunderstood tool of Root Cause Analysis (RCA), we should reflect its interpretation in our own environments. Think about it: when is RCA typically requested and applied in our environment? Based on my experience, it is typically requested and applied when…

Is the Human Being Really an “Asset”?

Reading Time: 3 minutes

We often hear our organizations referring to their workforce as their greatest ‘asset’. But are they really? Let’s first define ‘asset’ from a financial perspective:

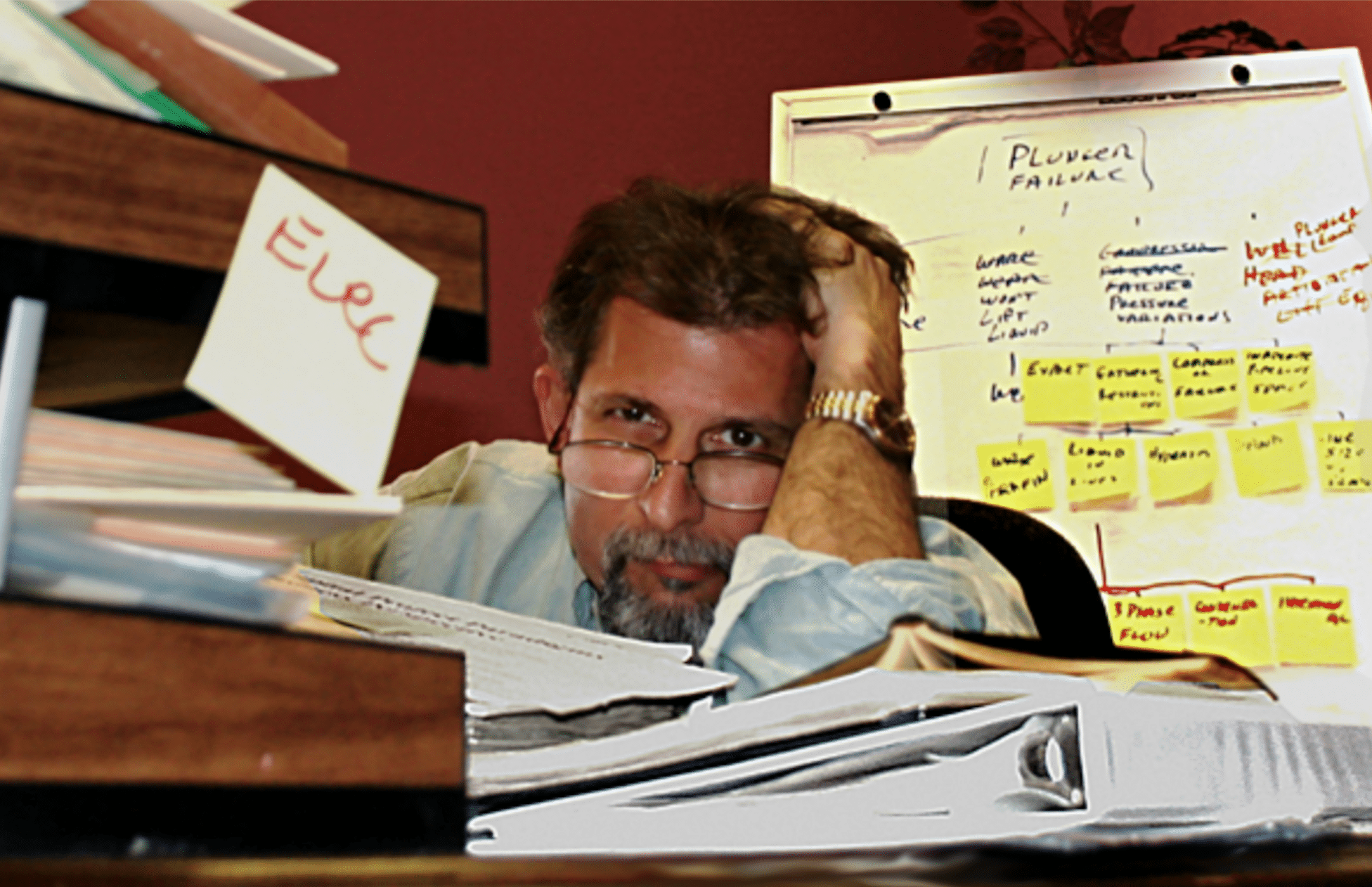

Post-Its: Their Love/Hate Relationship With RCA… Solutions Exist!

Reading Time: 9 minutes

WE LOVE OUR POST-ITS! When I’m asked who our primary competitors are, I quickly and simply reply ‘Post-Its’

Panning for Gold: Analyzing Chronic Failures

Reading Time: 3 minutes

The majority of times that a Root Cause Analysis (RCA) is ‘required’ is often due to some type of threshold of pain being met. Someone is hurt, we’ve had an environmental excursion, we lost a lot of money in throughput or equipment damage, we violated some regulation, etc. Essentially, when the ‘suits’ show up, something bad has happened and we

Proactive RCA: How to Break the Chains of Restraining Paradigms About RCA

Reading Time: 5 minutes

Traditionally RCA is only utilized after an event has occurred, so how can one call it proactive? This perception is explored through trying to understand the current paradigms that exist about RCA, what it is and when it is used. Do we really have to wait for an undesirable outcome to occur in order to use RCA?