3 Steps To Make RCAs More Impactful For Your Managers

Reading Time: 10 minutes

If managers knew what the overall power of a well supported Root Cause Analysis (RCA) effort meant for their bottom-line, they would be breaking down doors to implement the process. Unfortunately, this is often not the case, so this paper is an attempt to educate such individuals about the characteristics of an effective RCA methodology. The paper focuses on the

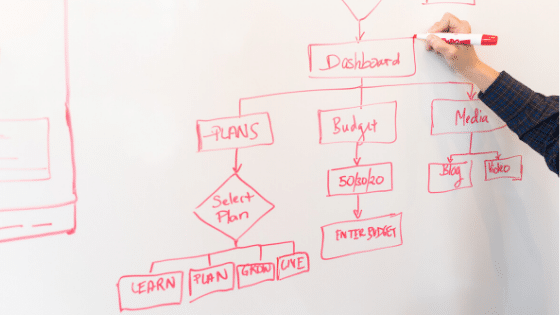

How to Perform Root Cause Analysis (RCA)?

Reading Time: 11 minutes

Understanding the reasons behind a company’s struggles isn’t always about not knowing how to fix them. Often, the true origins of these problems are hidden, and that’s why conducting a root cause analysis is so important for good leadership within an organization. When I give speeches around the world, I often poll my audiences about how they define ‘RCA’. The

The Secrets of How To Be a Good Reliability Engineer

Reading Time: 8 minutes

What does it take to be a good Reliability Engineer? Learn how to better utilize RCA thinking, develop Reliability habits, and how to build a business case with your management team. To increase your impact, you need to start thinking like an owner. Read on to learn The Secrets of Successful Reliability Engineers.

Aplicación de la metodología análisis causa raíz plus en las fallas recurrentes de un motor-ventilador

Reading Time: < 1 minute

Aplicación de la metodología análisis causa raíz plus en las fallas recurrentes de un motor-ventilador

Striving-for-Excellence-The-Art-and-Science-of-Instructional-Design

Reading Time: 2 minutes

Striving-for-Excellence-The-Art-and-Science-of-Instructional-DesignDownload PDF [15 pages] By: Ivor K. Davies, Professor of Education, Indiana University, Bloomington, Indiana {{cta(‘67251890-b3ff-4fac-9924-cc6ec02295a1’)}} “Intelligence, imagination, and knowledge are essential resources, but only effectiveness converts them into results. By themselves, they only set limits to what can be attained.” -Peter Drucker Article Summary: 15 pages: PDF Growth, Productivity, Improvement on Quality – The Reliability Approach – There are

NEW FEATURES To PROACTOnDemand!

Reading Time: 2 minutes

NEW FEATURES To PROACTOnDemand! {{cta(’85b48632-6501-48ce-9dc3-fc15b4de925f’)}}

Why Trending Data is Important

Reading Time: 2 minutes

Why Trending Data is Important Case Study: Predictive Activities – Trending {{cta(‘236ffbef-9183-4718-9aa0-b9b2e33e85c9’)}} This case history takes place in a packaging facility in Virginia. The packer on module E5 was checked for vibration integrity during a pre- machine care evaluation. A problem was detected in the folding arm gearbox. The frequency characteristics indicated a bearing was deteriorating. This seems very straight

Should a Procedure = Practice?

Reading Time: 2 minutes

Should a Procedure = Practice? I often ask my classes ‘If we follow our procedures to the letter, do nothing more and nothing less; would we optimize our system productivity, safety and reliability?’ The answer is NO. If anyone on this forum has ever worked in a union environment in the manufacturing world, they will attest that doing this (follow

Understanding the Principles of Reliability

Reading Time: 8 minutes

Understanding the Principles of Reliability Abstract: The Reliability Approach… “Something understood and practiced by engineers and highly specialized technicians,” is apt to be the first reaction of the line supervisor, “certainly not an area where I can be expected to become involved.” Although this reaction is understandable; nothing is farther from reality. Let’s explore why in this paper. Please read

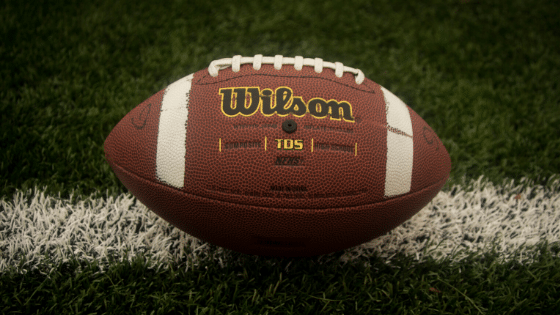

‘De-Flate Gate’ & RCA

Reading Time: 2 minutes

‘De-Flate Gate’ & RCA Originally published on January 23, 2015

Root Cause Analysis: The Justification Game

Reading Time: 4 minutes

Root Cause Analysis: The Justification Game Part 2 of 2 Maintenance Solutions In last month’s introductory article, we discussed some of the barriers to selling not only the concept of Root Cause Analysis (RCA) but also the recommendations generated as a result of these analyses. We also laid the framework for making better predictions by generating and accessing better data—namely

Root Cause Analysis: Investment or Expense?

Reading Time: 6 minutes

Root Cause Analysis: Investment or Expense? Abstract: In times that promise to be a financial challenge for many corporations, we must make decisions as to where to invest our scarce dollars and where to cut from our current operations. When faced with these decisions, we must be realistic and pragmatic about how short-term decisions impact our long-term goals. Yes, when times are