Subscribe for updates

Defining & Achieving the Reliability Culture

Reading Time: 31 minutes There is nothing more difficult to take in hand, more perilous to conduct, or more uncertain in its success than to take the lead in

Root Cause Analysis vs. Shallow Cause Analysis: What’s the Difference?

Reading Time: < 1 minute Does regulatory compliance with RCA guidelines ensure operational reliability? Operational Reliability involves the aggregation of Equipment, Process and Human Reliability methods and techniques. What is

‘Fantasy’ Maintenance: The Illusion of Best Practices

Reading Time: 4 minutes The following article was published in Plant Services earlier this year with the title, “Don’t get stuck in reactive mode – The world of fantasy

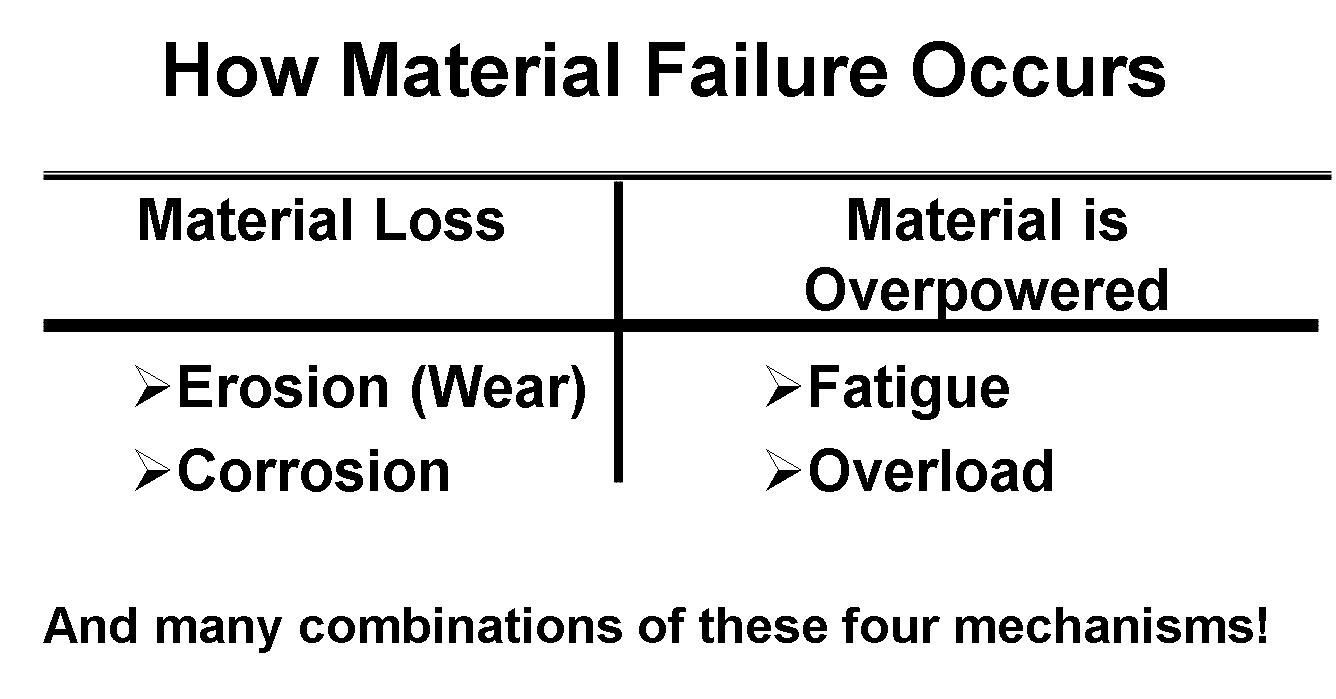

Fatigue & Overload: Part II, 4 Mechanisms of Component Failure

Reading Time: 4 minutes Author’s Note: I want to reiterate that this Series about reading the basic fracture surfaces, is for novices who often come into contact with such

Root Cause Analysis (RCA) Management Best Practices

Reading Time: 8 minutes RCA management is a structured and methodical approach to problem-solving, and it helps organizations learn from their mistakes and continuously improve their processes and systems

Trending Data Is Important to Predictive Activities

Reading Time: 4 minutes This case history takes place in a packaging facility in Virginia. The packer on module E5 was checked for vibration integrity during a pre-machine care

Saving $1 Million for Inland Steel

Reading Time: < 1 minute For some time now, Inland Steel has been committed to improving the reliability of our plant operations as a way to reduce costs, downtime and

Accepting We Could Be Part of the Problem

Reading Time: 6 minutes Abstract: No matter where we work, we will experience failures or ‘undesirable outcomes’ of some kind. As long as we work with other humans, this will indeed