7 Powerful Root Cause Analysis Tools and Techniques

- Root Cause Analysis Tools That Drive Results

- TL;DR

- What Tools Do You Use for Root Cause Analysis?

- 7 Common Root Cause Analysis Techniques

- 1. Ishikawa Fishbone Diagram (Cause-and-Effect Diagram)

- 2. Pareto Chart

- 3. 5 Whys Technique

- 4. Failure Mode and Effects Analysis (FMEA)

- 5. PROACT® RCA Method

- 6. Affinity Diagram

- 7. Fault Tree Analysis (FTA)

- Comparison of Root Cause Analysis Tools & Techniques

- Tying together RCA Techniques and Tools

- FAQs About Root Cause Analysis Tools and Techniques

Root Cause Analysis Tools That Drive Results

Root cause analysis tools help organizations uncover the real reasons behind recurring issues, prevent failures, and improve long-term performance. But not all tools are created equal. While RCA techniques like the Fishbone Diagram or 5 Whys provide the methods for investigation, the actual tools you use—whiteboards, Excel, Visio, or purpose-built RCA software—determine how effective and scalable your analysis will be.

In this article, we’ll cover both sides:

- 7 powerful RCA techniques every team should know

- The tools organizations commonly use (and their limitations)

- Why RCA software like EasyRCA offers the best way to streamline, collaborate, and deliver measurable results

Whether you’re just starting with RCA or looking to level up your approach, this guide will help you choose the right combination of techniques and tools to get lasting improvements.

TL;DR

Root cause analysis tools provide the platforms to apply RCA techniques effectively.

- Teams often start with whiteboards, Excel, or Visio to map problems.

- These tools work but are limited—they’re static, hard to share, and lack accountability.

- RCA software like EasyRCA solves these gaps by combining methods (Fishbone, 5 Whys,, logic trees) into one collaborative, trackable platform.

- Choosing the right mix of tools + techniques improves reliability, prevents repeat failures, and drives measurable business results.

What Tools Do You Use for Root Cause Analysis?

Most root cause analysis techniques—such as Fishbone Diagrams, 5 Whys, or Fault Tree Analysis—require a medium to capture and organize the team’s thinking. That’s where tools and software come in. These tools provide a workspace for applying RCA techniques, documenting findings, and managing corrective actions.

1. Whiteboards & Sticky Notes

Many RCA sessions start with brainstorming on a physical whiteboard or wall. While great for collaboration, the downsides are:

- Limited visibility once the session ends

- Difficult to archive or share remotely

- No easy way to track follow-up actions

2. Excel & Spreadsheets

Spreadsheets are one of the most common RCA tools for documenting causes, timelines, or FMEA ratings. But they:

- Aren’t built for visual methods like Fishbone or Fault Trees

- Can quickly become cluttered and hard to navigate

- Lack collaboration features

3. Visio, PowerPoint, and Diagramming Tools

Some teams rely on Visio, Lucidchart, or PowerPoint to draw cause-and-effect diagrams or logic trees. These are useful for creating visuals but:

- They’re static, not dynamic

- Updating them requires manual rework

- They don’t connect findings to corrective actions or task tracking

4. Dedicated RCA Software (Best Option)

Purpose-built Root Cause Analysis software like EasyRCA eliminates these gaps. With EasyRCA, you can:

- Build Fishbone Diagrams, Logic Trees, and 5 Whys directly in the platform

- Collaborate with team members in real time (no lost sticky notes)

- Link findings to corrective actions and owners

- Track and report on RCA effectiveness over time

👉 Unlike whiteboards or Excel, EasyRCA was designed specifically for RCA. It brings structure, visibility, and accountability to your entire process.

7 Common Root Cause Analysis Techniques

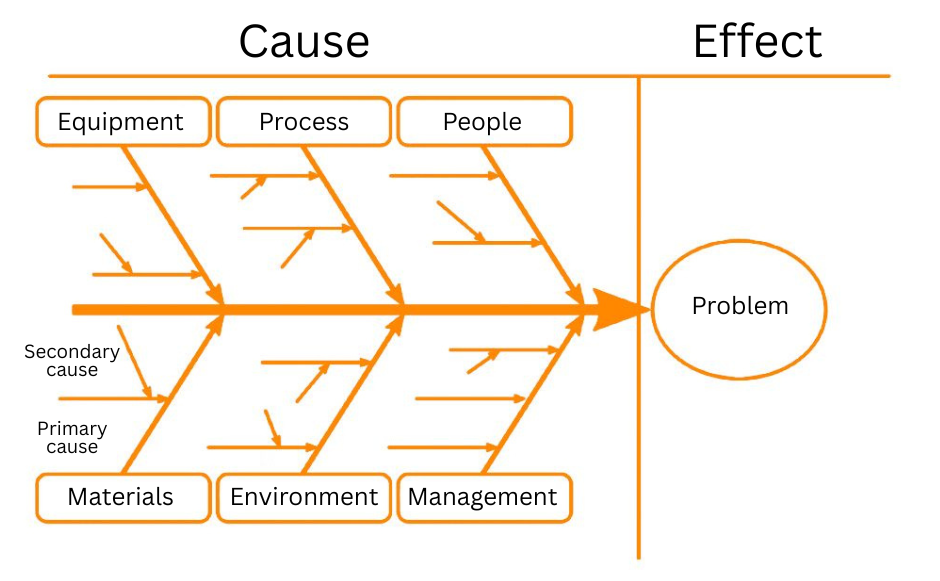

1. Ishikawa Fishbone Diagram (Cause-and-Effect Diagram)

The Ishikawa Fishbone Diagram is a visual root cause analysis tool that organizes potential causes of a problem into categories. Shaped like a fishbone, it helps teams brainstorm systematically by grouping causes under headings like Methods, Materials, Machines, People, and Environment.

👉 Best for: Complex problems with multiple potential causes.

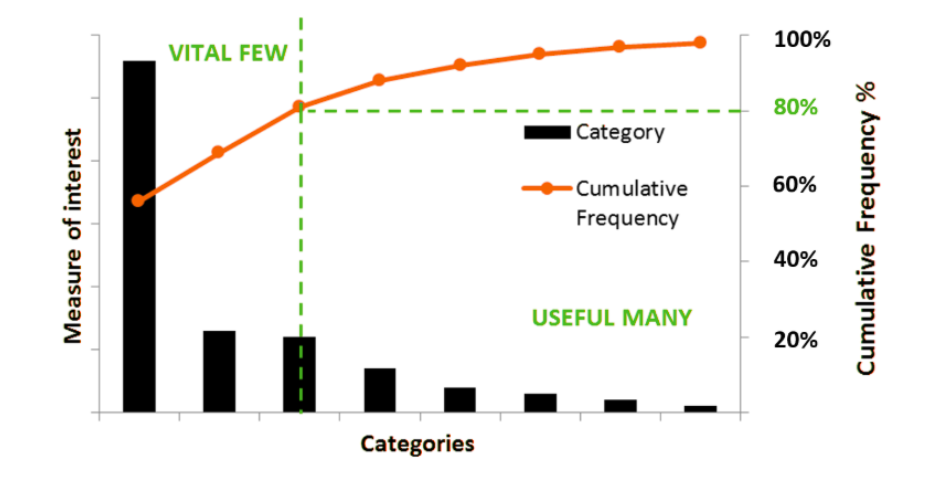

2. Pareto Chart

Based on the 80/20 Principle, the Pareto Chart helps prioritize the most significant causes of a problem. In most cases, 80% of failures come from just 20% of causes. By charting causes by frequency or impact, teams can focus on the biggest drivers of failure first.

👉 Best for: Identifying which issues deliver the highest ROI when solved.

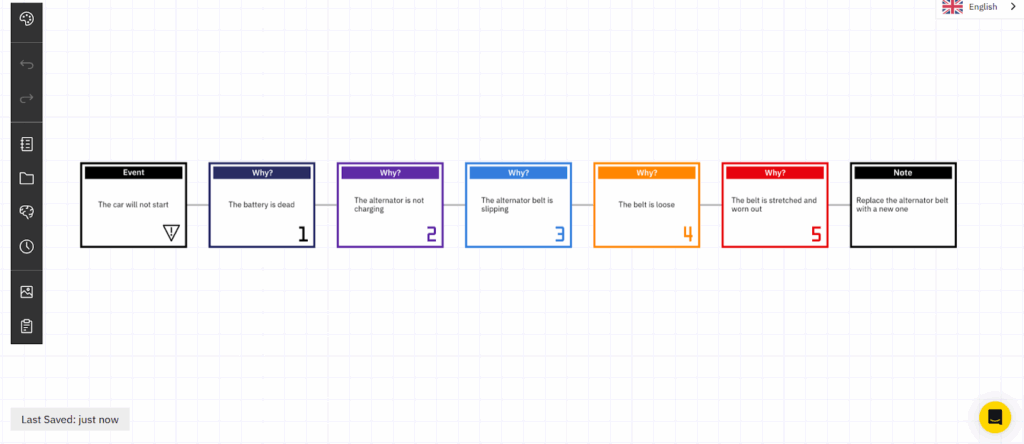

3. 5 Whys Technique

The 5 Whys method is a simple but effective tool that digs deeper by repeatedly asking “why?” (usually five times) until the root cause is uncovered. This method works best for straightforward issues but requires discipline to avoid guessing and instead base answers on evidence.

👉 Best for: Quick investigations of recurring, surface-level issues.

4. Failure Mode and Effects Analysis (FMEA)

FMEA is a proactive root cause analysis tool that anticipates where and how a process might fail. Teams rank risks by severity, occurrence, and detection, allowing them to prioritize corrective actions before problems escalate.

👉 Best for: High-risk industries where prevention is critical.

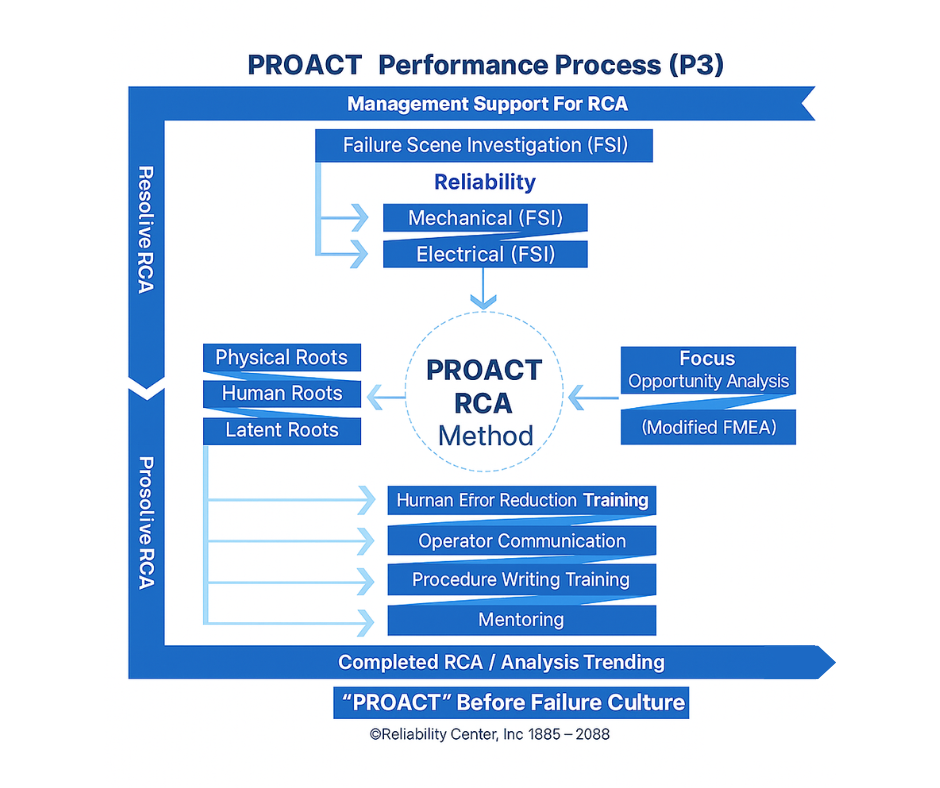

5. PROACT® RCA Method

The PROACT® RCA Method is a structured, evidence-driven approach developed by Reliability Center Inc. It is designed to tackle chronic, recurring failures that traditional methods often miss.

Steps include:

- Preserve Evidence & Acquire Data (using the 5 Ps: Parts, Position, People, Paper, Paradigms)

- Order Your Team & Assign Resources

- Analyze the Event using logic trees

- Communicate Findings & Recommendations

- Track & Measure Bottom-Line Results

👉 Best for: Organizations seeking measurable ROI from RCA programs.

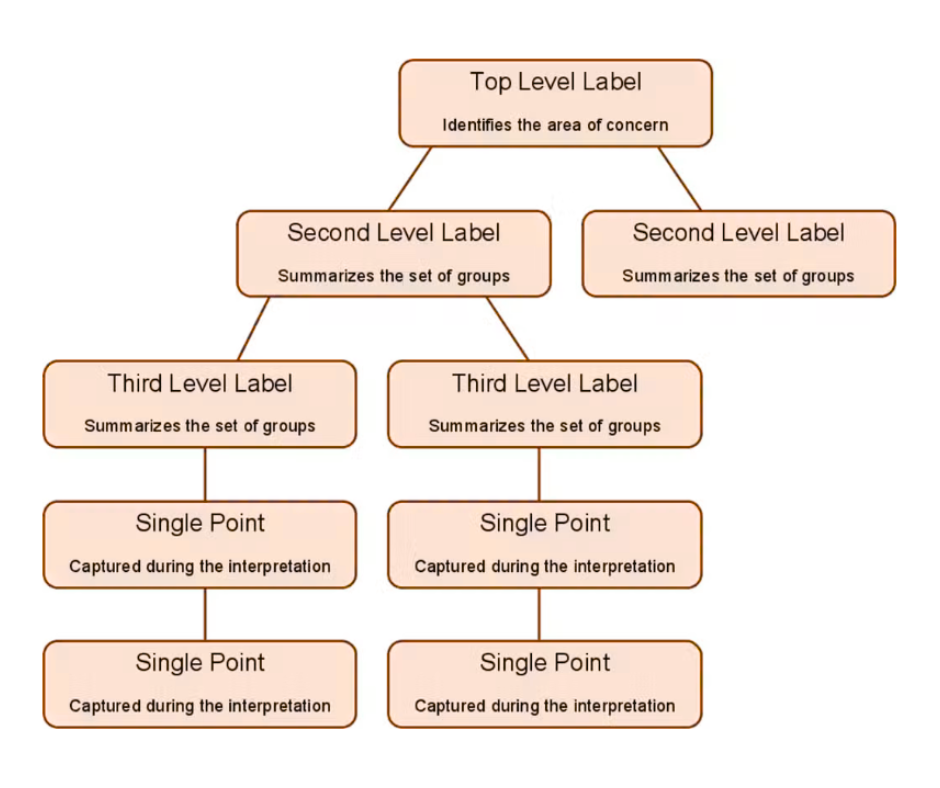

6. Affinity Diagram

The Affinity Diagram organizes large amounts of qualitative data into clusters based on natural relationships. It’s especially useful for turning brainstorming notes, survey feedback, or stakeholder input into structured insights.

👉 Best for: Finding themes and connections in complex or ambiguous problems.

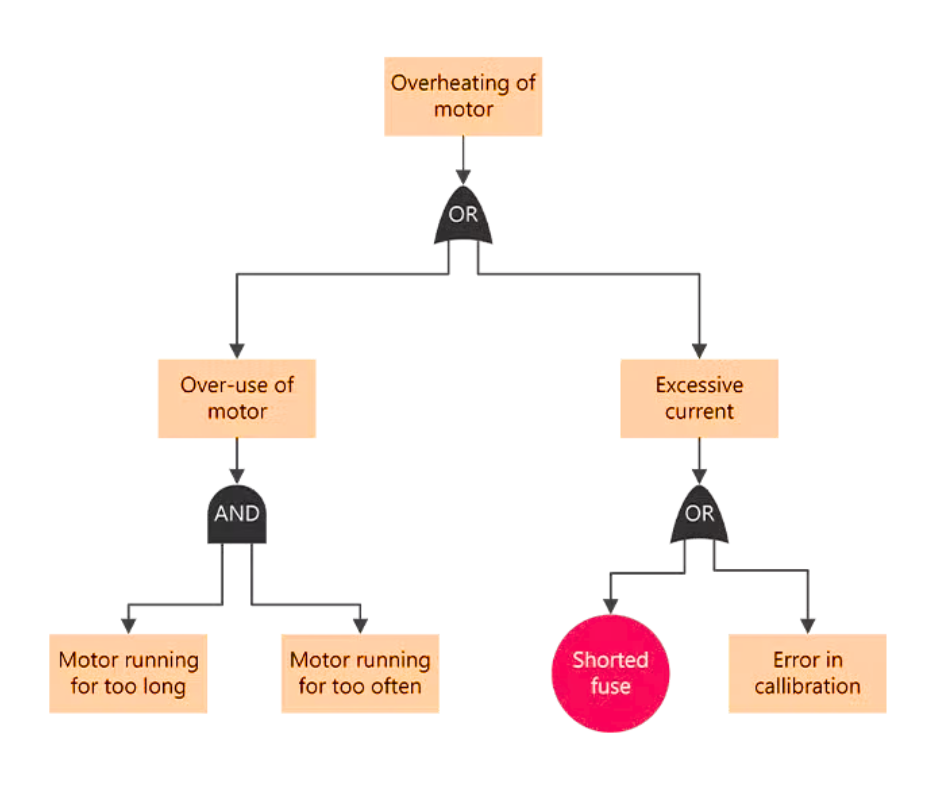

7. Fault Tree Analysis (FTA)

Fault Tree Analysis (FTA) is a top-down, deductive RCA tool used in safety-critical industries like aviation, nuclear energy, and healthcare. By mapping events in a tree structure, teams can see how multiple smaller issues combine into major system failures.

👉 Best for: High-risk, high-consequence problems that require exhaustive prevention.

Comparison of Root Cause Analysis Tools & Techniques

| Technique | Key Advantage | Typical Tool Used | Limitation |

| Fishbone Diagram | Visualizes complex relationships | Whiteboard / Visio | Static, hard to share |

| Pareto Chart | Prioritizes key drivers | Excel | Manual setup, no context |

| 5 Whys | Simple, fast analysis | Paper/Word Doc | Easy to oversimplify |

| FMEA | Proactively prevents failure | Excel | Time-consuming, error-prone |

| PROACT® RCA | Comprehensive & ROI-driven | Spreadsheets, and diagrams | Time- and resource-intensive without a structured process |

| Affinity Diagram | Organizes large data sets | Sticky Notes/Miro | Data gets lost over time |

| Fault Tree Analysis | Maps cascading failures | Diagram Tools | Hard to update & link actions |

Tying together RCA Techniques and Tools

The techniques like Fishbone Diagrams, Pareto Charts, or FMEA give you structured methods for uncovering causes. But the tools you use to apply them—whiteboards, spreadsheets, Visio diagrams—often make the process slow, static, and difficult to maintain. Once the session ends, data is hard to share, track, or revisit, and accountability can quickly get lost.

That’s why more organizations are turning to dedicated RCA software. A platform like EasyRCA brings all the methods together in one place, making it easier to build diagrams, run 5 Whys, or apply logic trees collaboratively. Unlike traditional tools, software gives teams visibility, structure, and accountability, ensuring that whichever RCA technique you choose, it’s applied effectively and leads to measurable, lasting results.

FAQs About Root Cause Analysis Tools and Techniques

Q: What is the best root cause analysis tool?

It depends on your problem. For quick issues, a 5 Whys on a whiteboard works. For complex or high-risk cases, methods like FMEA or PROACT® RCA and dedicated RCA software are more reliable.

Q: Can multiple tools or techniques be used together?

Yes. Many teams combine methods, such as starting with a Fishbone Diagram for brainstorming, then using Pareto Charts or FMEA to prioritize actions.

Q: Why not just use Excel or PowerPoint?

They work for one-off problems, but they weren’t built for RCA. They lack collaboration, structured workflows, and accountability features.

Q: How does EasyRCA compare?

EasyRCA combines Fishbone, 5 Whys, logic trees, and more into one platform—making RCA faster, collaborative, and trackable across the organization.

Q: Which industries benefit most from RCA?

RCA is widely used in manufacturing, healthcare, IT, aviation, and energy—but any organization facing recurring issues can benefit.

👉 Power up your root cause analysis with EasyRCA and streamline your entire process—from brainstorming to corrective action tracking. Start your free trial today.

Recent Posts

How to Improve Your RCA Program: A Practical Guide for Reliability Leaders

The 2026 Reliability Cost Curve: How World-Class Teams Bend It Downward

The Reliability Leader’s 2026 RCA Playbook: A Straightforward Guide to Starting the Year Strong

Why You Never Have Time for Root Cause Analysis (And How World-Class Teams Fix It)

Root Cause Analysis Software

Our RCA software mobilizes your team to complete standardized RCA’s while giving you the enterprise-wide data you need to increase asset performance and keep your team safe.

Root Cause Analysis Training