5 Whys Root Cause Analysis vs. Logic Trees: Which One Works Best?

- What Is 5 Whys Root Cause Analysis?

- What Is a Logic Tree in Root Cause Analysis?

- 5 Whys vs. Logic Tree: A Side-by-Side Comparison

- When to Use 5 Whys vs. Logic Trees

- Real-World Example: From 5 Whys to Logic Tree

- How Software Makes Both 5 Whys and Logic Trees Even Better

- Frequently Asked Questions

- Choosing the Right RCA Method

5 Whys Root Cause Analysis is one of the most popular methods for investigating problems, but it isn’t always enough on its own. For more complex issues, teams often turn to logic trees to explore multiple potential causes.

So, how do you know when to use the simplicity of 5 Whys versus the depth of a logic tree? This post compares the two approaches, highlighting their strengths, weaknesses, and practical applications. We’ll also explore how tools like EasyRCA integrate both methods, helping teams choose the right level of analysis for each incident.

What Is 5 Whys Root Cause Analysis?

The 5 Whys technique involves repeatedly asking “why?” to drill down to the underlying cause of a problem.

Example:

- Problem: The machine stopped.

- Why? → Fuse blew.

- Why? → Motor overloaded.

- Why? → Bearing not lubricated.

- Why? → Lubrication pump failed.

- Why? → Maintenance schedule not followed.

| Strengths | Weaknesses |

| Simple and quick | Can oversimplify complex issues |

| Easy for small teams to apply | A linear approach may miss multiple causes |

| Requires no advanced training or software | High risk of bias (“stopping too early”) |

| Great for minor, straightforward problems | Depends heavily on facilitator’s skill |

What Is a Logic Tree in Root Cause Analysis?

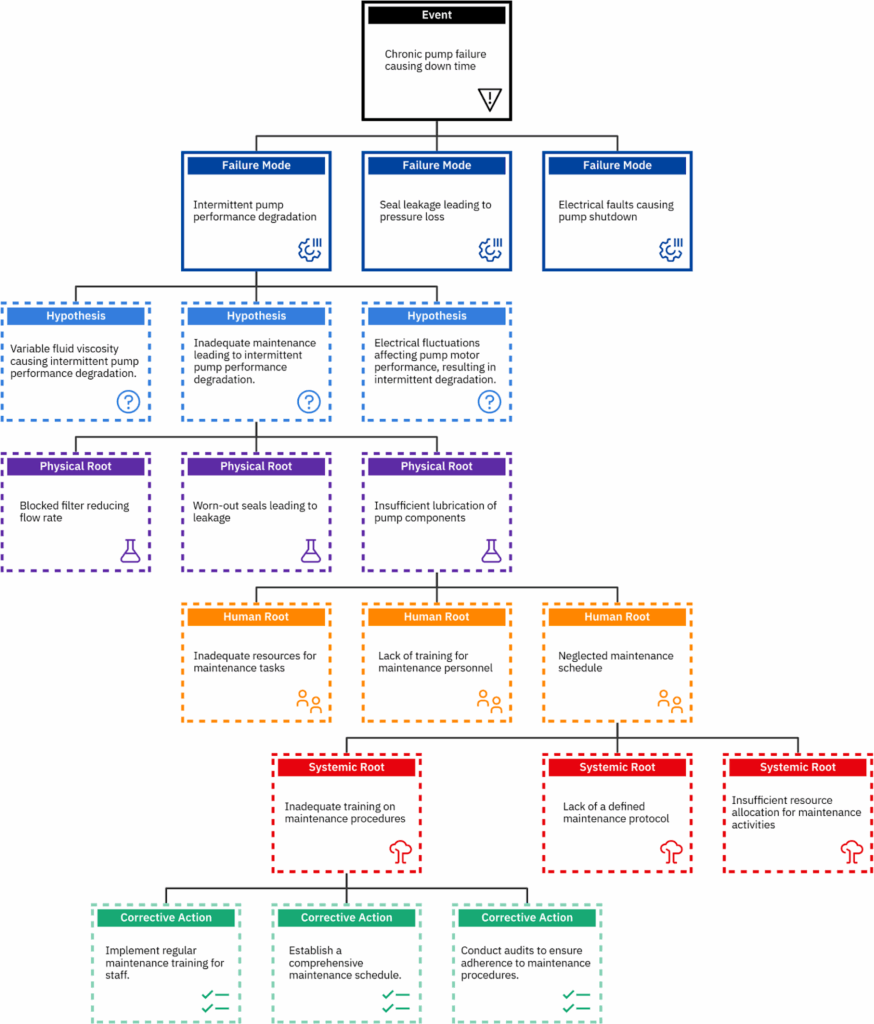

A logic tree (sometimes called a cause-and-effect tree) visually maps out all possible contributing factors. Instead of following a single chain of “whys,” a logic tree branches into multiple cause pathways.

Example Application:

When a pump repeatedly fails, a logic tree maps failure modes like performance degradation, seal leakage, or electrical faults. Hypotheses are tested, revealing physical roots such as a blocked filter, worn seals, or poor lubrication. Human causes include missed inspections and skipped maintenance, while systemic causes stem from gaps in the preventive maintenance program and training.

| Strengths | Weaknesses |

| Captures multiple, parallel causes | Requires more time and occasionally training |

| Provides a visual structure for teams | Can be overwhelming without a structured tool |

| Reduces bias by forcing broader exploration | Not always necessary for minor incidents |

| Suitable for complex, high-impact incidents | – |

5 Whys vs. Logic Tree: A Side-by-Side Comparison

| Criteria | 5 Whys Root Cause Analysis | Logic Tree |

| Complexity | Low – simple, linear | High-branching, multi-cause |

| Time Required | Short | Longer |

| Training Needed | Minimal | Moderate to advanced |

| Bias Risk | High (single-path focus) | Lower (forces broader thinking) |

| Best For | Minor issues | Complex, critical failures and recurring issues |

| Common Pitfalls | Stopping too soon | Over-analysis if poorly scoped |

Key takeaway: Start with 5 Whys for simple issues, but escalate to logic trees when the problem has multiple possible causes, safety implications, or significant financial risk.

When to Use 5 Whys vs. Logic Trees

Use 5 Whys When:

- The problem is small or routine.

- The team has limited time or experience.

- Quick learning is the main goal.

Use Logic Trees When:

- The incident has multiple potential pathways.

- Safety, compliance, or financial stakes are high.

- Problems recur despite past investigations.

- You need a visual tool to align multiple stakeholders.

Real-World Example: From 5 Whys to Logic Tree

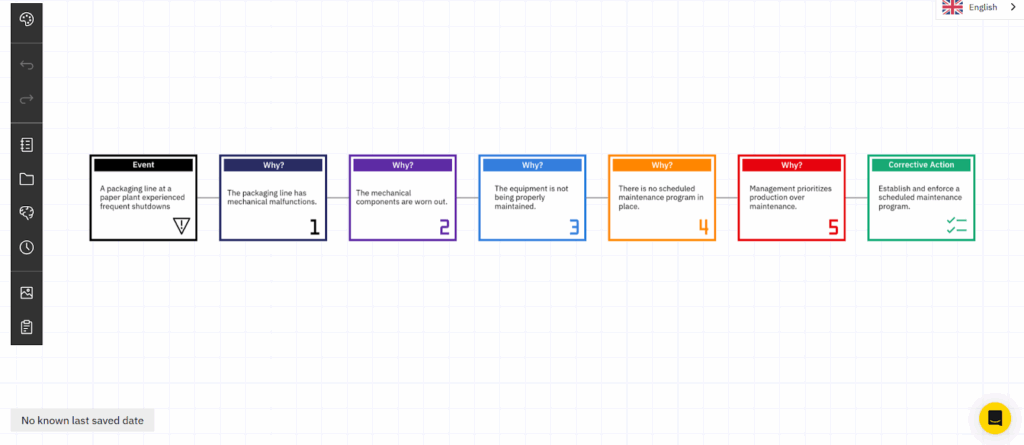

A packaging line at a paper plant experienced frequent shutdowns. The team first applied 5 Whys Root Cause Analysis:

- Why did the line stop? → Conveyor belt jammed.

- Why did it jam? → Sensors misaligned.

- Why? → Vibration loosened the mounting.

This led to a temporary fix—tightening sensors. But the problem kept coming back.

The team then escalated to a logic tree, which revealed additional contributing causes: poor supplier quality on replacement belts, inconsistent operator checks, and outdated maintenance intervals. By addressing all branches, downtime was finally reduced.

This example shows why it’s important to scale your method to the complexity of the problem.

How Software Makes Both 5 Whys and Logic Trees Even Better

On their own, 5 Whys and logic trees can be powerful, but they also come with challenges—bias, inconsistency, and lost insights over time. Software like EasyRCA removes those barriers so your team can get more value from every investigation.

- Simplify 5 Whys – Templates and guided workflows keep the process focused, reduce bias, and prevent teams from stopping too early.

- Strengthen Logic Trees – A visual platform makes it easy to branch into multiple causes, test hypotheses, and capture human and systemic factors without getting overwhelmed.

- Seamless escalation – Start with a simple 5 Whys and expand into a logic tree instantly when the problem proves more complex.

- Consistent data, every time – All RCAs, from quick fixes to high-stakes failures, are captured in one system so you can spot trends, report outcomes, and build a stronger reliability program.

With EasyRCA, you don’t have to choose between simplicity and depth. The software makes both methods more effective—and ensures your team always has the right level of analysis for the job.

Frequently Asked Questions

Is 5 Whys Root Cause Analysis outdated?

No. It remains a valuable tool for simple problems. The key is knowing when to escalate to more advanced methods like logic trees.

How do I know when to switch from 5 Whys to a logic tree?

If your team reaches multiple possible causes, runs into recurring issues, or deals with high-stakes incidents, a logic tree is the better option.

Can I use both methods together?

Yes. Many organizations start with 5 Whys and then expand into a logic tree if the issue proves more complex. EasyRCA supports this workflow.

Choosing the Right RCA Method

The debate of 5 Whys Root Cause Analysis vs. logic trees isn’t about which method is “better.” It’s about choosing the right level of analysis for the problem at hand.

- Use 5 Whys for quick, simple issues.

- Use logic trees for complex, high-stakes investigations.

- Use EasyRCA to bring both together in one structured tool.

If you’re ready to move from understanding RCA to applying it consistently and effectively, explore how EasyRCA can help.

👉 Visit EasyRCA.com to request a demo, download a free template, or start your trial today.

Recent Posts

5 Whys Root Cause Analysis vs. Logic Trees: Which One Works Best?

Root Cause Analysis Example: From Incident to Insight in 5 Steps

How Root Cause Analysis Training Builds a Culture of Reliability

AI in Root Cause Analysis: How Emerging Tools Are Changing Reliability

Root Cause Analysis Software

Our RCA software mobilizes your team to complete standardized RCA’s while giving you the enterprise-wide data you need to increase asset performance and keep your team safe.

Root Cause Analysis Training