AI and Site Reliability Engineers: Lessons from the Field.

Reading Time: 3 minutes

Root cause analysis has traditionally been a reactive discipline—often only activated after something breaks. While that will always be its core, emerging AI technologies are giving reliability professionals more information before a failure occurs—data that can make post-event RCAs faster and more informed. At the recent Mainstream Reliability Conference, a standout session titled “Empowered Reliability Engineers to Predict Failures Using

Smarter, Faster, Deeper: How AI Is Transforming Root Cause Analysis in Software and Beyond

Reading Time: 3 minutes

For years, root cause analysis (RCA) has relied on structured techniques like the 5 Whys, Fault Tree Analysis (FTA), and Cause-and-Effect (Fishbone) Diagrams to help teams understand why problems happen., and how to keep them from coming back. But as systems become more complex and data becomes more abundant, a new player has entered the RCA process: artificial intelligence. In

North America’s Looming Power Shortfall: A Root Cause Analysis for the Grid—and Beyond

Reading Time: 2 minutes

A new Utility Dive piece highlights how the North American Electric Reliability Corporation (NERC) had to rethink MISO’s shortfall risk when a data slip changed how the region’s summer capacity was forecast. It’s a wake-up call: small data errors can lead to big reliability surprises if teams don’t verify, monitor, and adapt fast. So, what can we learn? Let’s look

Preventing EV Charger Downtime: How Smart Test Strategies Act as Root Cause Analysis in Action

Reading Time: 3 minutes

The push for widespread electric vehicle (EV) adoption has put a fresh spotlight on an old reliability challenge: keeping critical equipment running when drivers need it most. For EV charging networks, that means chargers must be ready, safe, and efficient every time a car pulls up. But as the recent Charged EVs report on test strategies points out, the gap

UK Retail Cyberattacks: What M&S, Harrods & Co-op Reveal About Cybersecurity and Root Cause Analysis

Reading Time: 3 minutes

In April 2025, prominent UK retailers Marks & Spencer (M&S), Co-op, and Harrods faced significant cyberattacks that disrupted operations and exposed vulnerabilities in their cybersecurity frameworks. These incidents highlight the critical need for thorough root cause analysis (RCA) to understand and mitigate such threats effectively. The Incidents: A Brief Overview Marks & Spencer (M&S) M&S experienced a major cyberattack over

Richmond Water Crisis Exposes Infrastructure Vulnerabilities: Why RCA Is Key to Long-Term Solutions

Reading Time: 4 minutes

What Happened in Richmond? In the early hours of May 27, 2025, a large portion of Richmond, Virginia woke up to a frustrating and unexpected problem—dry taps and low water pressure. What began as overnight maintenance work quickly led to a city-wide boil water advisory, with officials urging residents not to drink or cook with tap water unless it was

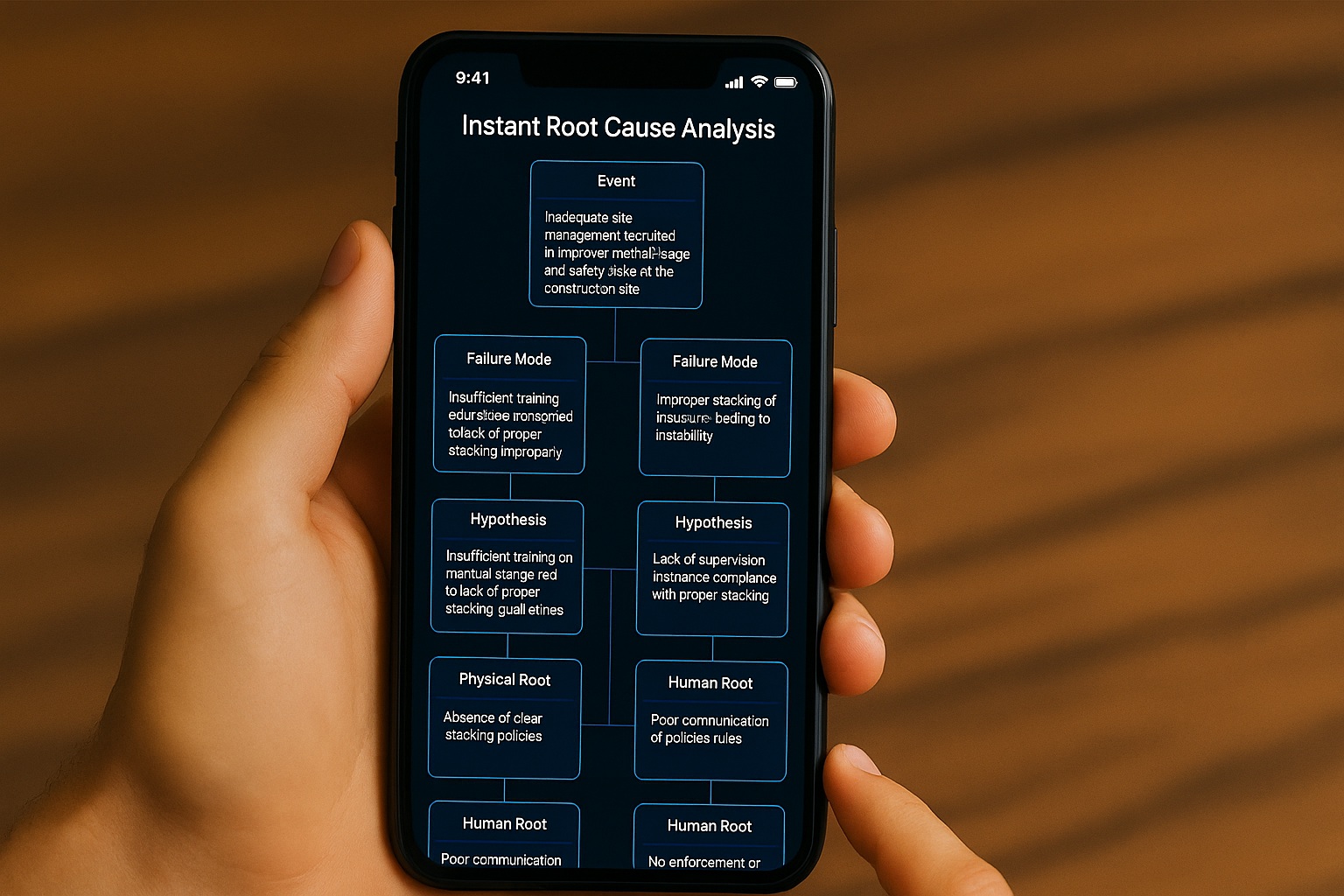

Introducing RCA Turbo: Instant Root Cause Analysis with a Snap or a Sentence

Reading Time: 4 minutes

Introduction Root cause analysis (RCA) is essential—but let’s face it, it’s often time-consuming. What if you could bypass the heavy documentation and jump straight into solving the problem? That’s where RCA Turbo comes in. Now available in the EasyRCA app, RCA Turbo is designed for speed and simplicity, allowing anyone to create a complete root cause analysis in seconds—just by

Unpacking the Iberian Peninsula Blackout: How Root Cause Analysis Can Illuminate Grid Vulnerabilities

Reading Time: 3 minutes

On April 28, 2025, Spain and Portugal experienced one of the most significant power outages in European history, plunging millions into darkness, halting transportation, and disrupting critical services. The blackout, which lasted several hours, affected major cities including Madrid, Lisbon, and Barcelona, leading to widespread chaos and raising pressing questions about the resilience of modern power grids. What Happened? At

Unpacking the Bursa Malaysia Cybersecurity Breach: How Root Cause Analysis Can Keep Your Systems Safe

Reading Time: 3 minutes

Have you been following the headlines about Bursa Malaysia’s recent cybersecurity breach? According to an article by The Edge, several online trading accounts were compromised on April 24, 2025, leading to unauthorised share purchases on Bursa Malaysia. While the immediate headlines focused on sudden spikes in penny-stock prices and millions lost through illicit gains, the true question for business leaders

Case Study: Ash Grove Cement’s Enhanced Reliability with EasyRCA

Reading Time: 3 minutes

Company OverviewAsh Grove Cement, a leading North American producer of cement with 12 manufacturing plants and 41 distribution terminals across the U.S. and Canada, is committed to enhancing its operational efficiency, reliability, and safety across its facilities. As part of their continuous improvement efforts, Ash Grove Cement implemented EasyRCA, a web-based root cause analysis (RCA) software, to address challenges with

Manufacturing Smarter – How Root Cause Analysis and Automation are Revolutionizing Film Production

Reading Time: 2 minutes

A New Era of Film Production Efficiency The manufacturing industry is seeing a transformation in plastic film production. A recent innovation introduced real-time monitoring technology that enables manufacturers to detect defects and material inconsistencies before production bottlenecks occur. This system enhances automated quality control, allowing production teams to address film-stretching issues, thickness inconsistencies, and raw material defects before they affect

A Breakthrough in Food Safety through Root Cause Analysis – Listeria Contamination in the Food Industry

Reading Time: 2 minutes

A Breakthrough in Food Safety: New Diagnostic Solution for Listeria Contamination In the ever-evolving landscape of food safety, Listeria monocytogenes remains a persistent and dangerous threat. Contaminated food can lead to severe health risks, costly recalls, and legal ramifications. Recently, a breakthrough diagnostic solution was introduced to the food industry to detect and analyze the root causes of Listeria contamination