Corporate Memory: Capturing Employee Experience Before they Retire in the Tropics!

Reading Time: 3 minutes

Corporate Memory: Capturing Employee Experience Before they Retire in the Tropics! Robert J. Latino, CEO, Reliability Center, Inc., www.reliability.com Why do our Generally Accepted Accounting Principles (GAAP) dictate that equipment is an asset and our employees are liabilities? Don’t our executives always tell us ‘our people are our greatest assets?’ How come our financials don’t support their assertion? How come during

The ‘Soft Side’ of RCA: Management’s Role in ‘Effective’ Training

Reading Time: 5 minutes

The ‘Soft Side’ of RCA: Management’s Role in ‘Effective’ Training By Robert J. Latino, CEO, Reliability Center, Inc. Abstract: In an era of rapidly advancing technology, the need for training to keep up is imperative. But training alone is not the panacea to a facility’s problems. Management’s must be aware that the environment in which their people work, will either progress or obstruct

Effective Root Cause Analysis Means Accepting We Could Be Part of the Problem

Reading Time: 6 minutes

Abstract: No matter where we work, we will experience failures or ‘undesirable outcomes’ of some kind. As long as we work with other humans, this will indeed be the case. These failures may surface in the form of production delays, injuries, customer complaints, missed deadlines, lost profits, legal claims and the like. Effective Root Cause Analysis Means Accepting We Could Be Part of

What is the Correlation Between Root Cause Analysis and Swiss Cheese?

Reading Time: < 1 minute

What is the Correlation Between Root Cause Analysis and Swiss Cheese? As long as humans are involved in running our organizations, there will be holes (vulnerabilities) in our cheese. This is why I state that we will never have American cheese (no holes) representing our safety systems, because this would imply they would be failsafe and not impenetrable. The Swiss cheese

Why Reliability Professionals Can Frustrate the Hell Out Of Others!

Reading Time: 6 minutes

Why Reliability Professionals Can Frustrate the Hell Out Of Others! I guess I am writing this just as a reality/sanity check to see if it’s just me, or do my peers in the Reliability profession have the same problems I do, communicating with non-Reliability professionals? If anyone has been in the Reliability game for a long period of time (I

The 4 Physical Failure Mechanisms of Component Failure: The Basics (Part I)

Reading Time: 3 minutes

This article is directed at those ‘first responders’ who arrive immediately at the failure scene. These are the people who have to ensure the area is safe, preserve the scene for investigators and contribute to a plan to expedite a quick, safe return to production norms. Many do not understand how valuable failed parts are to the metallurgical/forensic investigators. Broken

Part III: The 4 Basic Physical Failure Mechanisms of Component Failure: Overload

Reading Time: 3 minutes

Author’s Note: I want to reiterate that this Series about reading the basic fracture surfaces, is for novices who often first come into contact with such failed components. This Series is about the basics (101), and is intended to give readers an appreciation for the value of such ‘broken’ parts to an effective investigation/RCA. While this information will be rudimentary

Tips for Examining Rolling Element Bearings: Prepping for a Root Cause Analysis (RCA)

Reading Time: 7 minutes

Abstract. In our last series highlighting the 4 primary Failure Modes (FM) of component failures (erosion, corrosion, fatigue and overload), we discussed how to read fractured surfaces. In this follow up series, we will take a look at tips on how to collect, preserve and examine such failed components.

Tips for Examining Shafts: Prepping for a Root Cause Analysis (RCA)

Reading Time: 7 minutes

Tips for Examining Shafts: Prepping for a Root Cause Analysis (RCA) Note to Series Readers. To those following this Series, I will apologize for the front-end redundancy. I am doing so for those that are NOT following the Series and will read these articles independent of each other. If you are following the series (Thank You!) and proceed past the front-end

How Failed Parts Work Into an RCA

Reading Time: 9 minutes

How Failed Parts Work Into an RCA Author’s Note: I want to reiterate that this Series about reading the basic fracture surfaces, is for novices who often come into contact with such failed components. This Series is about the basics (101), and is intended to give readers an appreciation for the value of such ‘broken’ parts to an effective investigation/RCA.

Recognizing Basic Gear Fatigue Failure Patterns

Reading Time: 3 minutes

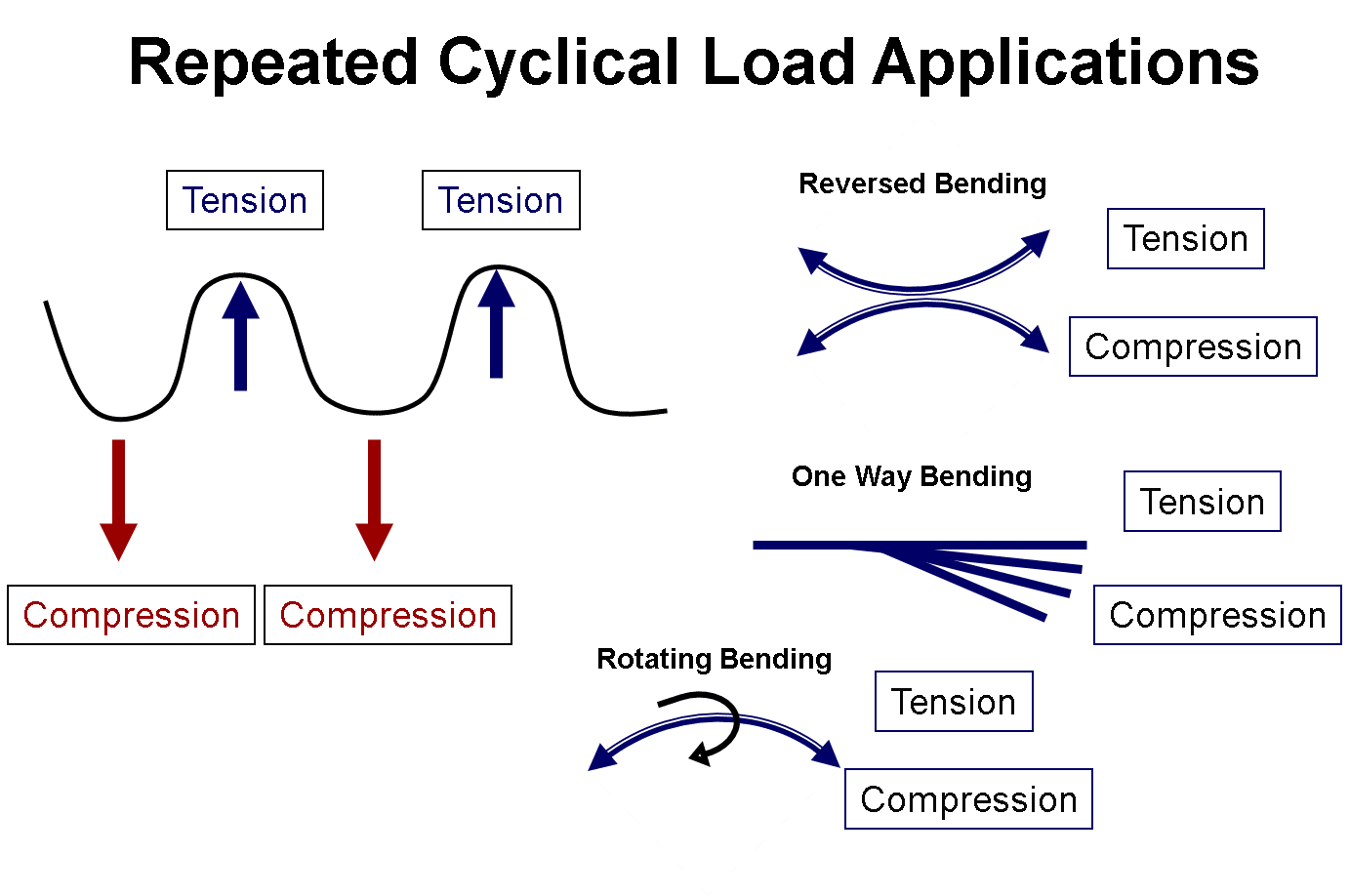

What are Fatigue Failure Patterns? In our prior blog on Fatigue we discussed the various cyclical loading applications. Let’s review them again with this graphic. Basic Characteristics of Gear Fatigue Now let’s get a little bit more specific and discuss the basic characteristics of Gear fatigue. Some of these basics are: Let’s run through some failed parts and see if we can

A Mechanic’s Story: Basic Component Fatigue

Reading Time: 8 minutes

In this article, we are going to delve into Fatigue (because it is the most common fracture pattern) and see how we can use an evidence-based, deductive logic process to determine what elements of Fatigue may have been at play. We are trying to create an intellectual curiosity within the front lines about ‘making the call’…is it Fatigue, or some