The Importance of Root Cause Analysis in Health, Safety, and Environment (HSE)

Health, Safety, and Environment (HSE) are critical pillars of success for industrial operations. A robust HSE program protects employees, ensures compliance, and minimizes environmental impact. However, even the most comprehensive HSE strategies are not immune to incidents. When accidents, environmental violations, or health concerns arise, Root Cause Analysis (RCA) becomes an indispensable tool for driving improvements and preventing recurrence.

The Connection Between RCA and HSE

Root Cause Analysis is a systematic method of identifying the underlying causes of problems. In the context of HSE, RCA helps organizations move beyond superficial fixes to address the systemic issues that contribute to incidents. For example, an RCA can uncover whether an accident stemmed from inadequate training, poorly maintained equipment, or flawed procedures.

By integrating RCA into HSE programs, organizations can:

- Enhance workplace safety.

- Reduce environmental risks.

- Improve employee health outcomes.

- Strengthen compliance with industry regulations.

- Improve employee morale as repetitive problems are eliminated.

How RCA Strengthens HSE Efforts

- Proactive Incident Prevention

RCA doesn’t just analyze past incidents—it identifies potential risks that could lead to future ones. Organizations can implement proactive measures to prevent more significant issues by examining near-misses or minor incidents. - Uncovering Systemic Issues

In many HSE incidents, the root cause lies in deeper organizational problems, such as insufficient safety culture or gaps in communication. RCA provides a framework to uncover and address these systemic issues, leading to long-term improvements. - Supporting Compliance

Regulatory bodies often require detailed investigations following HSE incidents. RCA ensures organizations can provide thorough documentation, demonstrate due diligence, and implement corrective actions to meet compliance requirements. - Cost Reduction

Incidents related to HSE can lead to significant costs—medical expenses, equipment damage, environmental fines, and production downtime. By addressing the root cause, organizations reduce the likelihood of repeated incidents, saving money and resources.

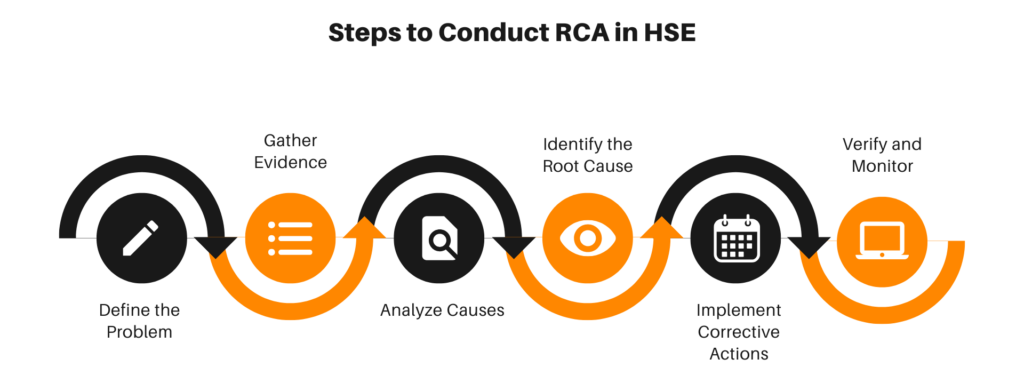

Steps to Conduct RCA in HSE

- Define the Problem: Clearly outline the nature of the incident. Was it a workplace injury, a chemical spill, or an ergonomic issue?

- Gather Evidence: Collect data like incident reports, equipment logs, and witness statements.

- Analyze Causes: Use RCA tools like the Fishbone Diagram, 5 Whys, or Fault Tree Analysis to identify contributing factors.

- Identify the Root Cause: Determine the fundamental issue that allowed the incident to occur.

- Implement Corrective Actions: Develop and execute solutions, such as updating safety protocols, providing additional training, or redesigning workflows.

- Verify and Monitor: Ensure corrective actions address the root cause and monitor progress over time.

Example: Equipment Failure in a Manufacturing Plant

Imagine a manufacturing plant experiences a toxic gas leak due to faulty equipment. An RCA investigation might reveal the root cause was a lack of preventive maintenance. Corrective actions could include implementing a maintenance schedule, providing technician training, and installing automated monitoring systems to detect leaks.

The Role of Technology in RCA for HSE

Modern RCA tools enhance investigations by leveraging technology:

- Data Analytics: Advanced analytics help identify patterns and trends in incident data.

- IoT Integration: Internet of Things (IoT) devices provide real-time monitoring of equipment and environmental conditions.

- Collaboration Tools: Digital platforms enable cross-departmental collaboration to address complex HSE challenges.

Conclusion

Root Cause Analysis is a cornerstone of effective HSE management. By systematically identifying and addressing the root causes of incidents, organizations can create safer workplaces, protect the environment, and ensure compliance. Incorporating RCA into HSE programs is not just a best practice—it’s a necessity for long-term success. With the right tools, processes, and commitment, RCA empowers organizations to build a culture of continuous improvement and resilience.

Recent Posts

How to Improve Your RCA Program: A Practical Guide for Reliability Leaders

The 2026 Reliability Cost Curve: How World-Class Teams Bend It Downward

The Reliability Leader’s 2026 RCA Playbook: A Straightforward Guide to Starting the Year Strong

Why You Never Have Time for Root Cause Analysis (And How World-Class Teams Fix It)

Root Cause Analysis Software

Our RCA software mobilizes your team to complete standardized RCA’s while giving you the enterprise-wide data you need to increase asset performance and keep your team safe.

Root Cause Analysis Training