3 Steps To Make RCAs More Impactful For Your Managers

Reading Time: 10 minutes

If managers knew what the overall power of a well supported Root Cause Analysis (RCA) effort meant for their bottom-line, they would be breaking down doors to implement the process. Unfortunately, this is often not the case, so this paper is an attempt to educate such individuals about the characteristics of an effective RCA methodology. The paper focuses on the

How to Perform Root Cause Analysis (RCA)?

Reading Time: 11 minutes

Understanding the reasons behind a company’s struggles isn’t always about not knowing how to fix them. Often, the true origins of these problems are hidden, and that’s why conducting a root cause analysis is so important for good leadership within an organization. When I give speeches around the world, I often poll my audiences about how they define ‘RCA’. The

The Secrets of How To Be a Good Reliability Engineer

Reading Time: 8 minutes

What does it take to be a good Reliability Engineer? Learn how to better utilize RCA thinking, develop Reliability habits, and how to build a business case with your management team. To increase your impact, you need to start thinking like an owner. Read on to learn The Secrets of Successful Reliability Engineers.

What is RCA? Separating the Tools from the Methodologies

Reading Time: 5 minutes

What is RCA? Separating the Tools from the Methodologies By Bob Latino, CEO, Reliability Center, Inc. Abstract: If we have heard it once, we have heard it a million times – “let’s do an RCA on that failure”. The problem here is that phrase will mean something different to everyone who says it. What is an RCA? That is a question even the notable

The 4 Physical Failure Mechanisms of Component Failure: The Basics (Part I)

Reading Time: 3 minutes

This article is directed at those ‘first responders’ who arrive immediately at the failure scene. These are the people who have to ensure the area is safe, preserve the scene for investigators and contribute to a plan to expedite a quick, safe return to production norms. Many do not understand how valuable failed parts are to the metallurgical/forensic investigators. Broken

Part III: The 4 Basic Physical Failure Mechanisms of Component Failure: Overload

Reading Time: 3 minutes

Author’s Note: I want to reiterate that this Series about reading the basic fracture surfaces, is for novices who often first come into contact with such failed components. This Series is about the basics (101), and is intended to give readers an appreciation for the value of such ‘broken’ parts to an effective investigation/RCA. While this information will be rudimentary

Tips for Examining Shafts: Prepping for a Root Cause Analysis (RCA)

Reading Time: 7 minutes

Tips for Examining Shafts: Prepping for a Root Cause Analysis (RCA) Note to Series Readers. To those following this Series, I will apologize for the front-end redundancy. I am doing so for those that are NOT following the Series and will read these articles independent of each other. If you are following the series (Thank You!) and proceed past the front-end

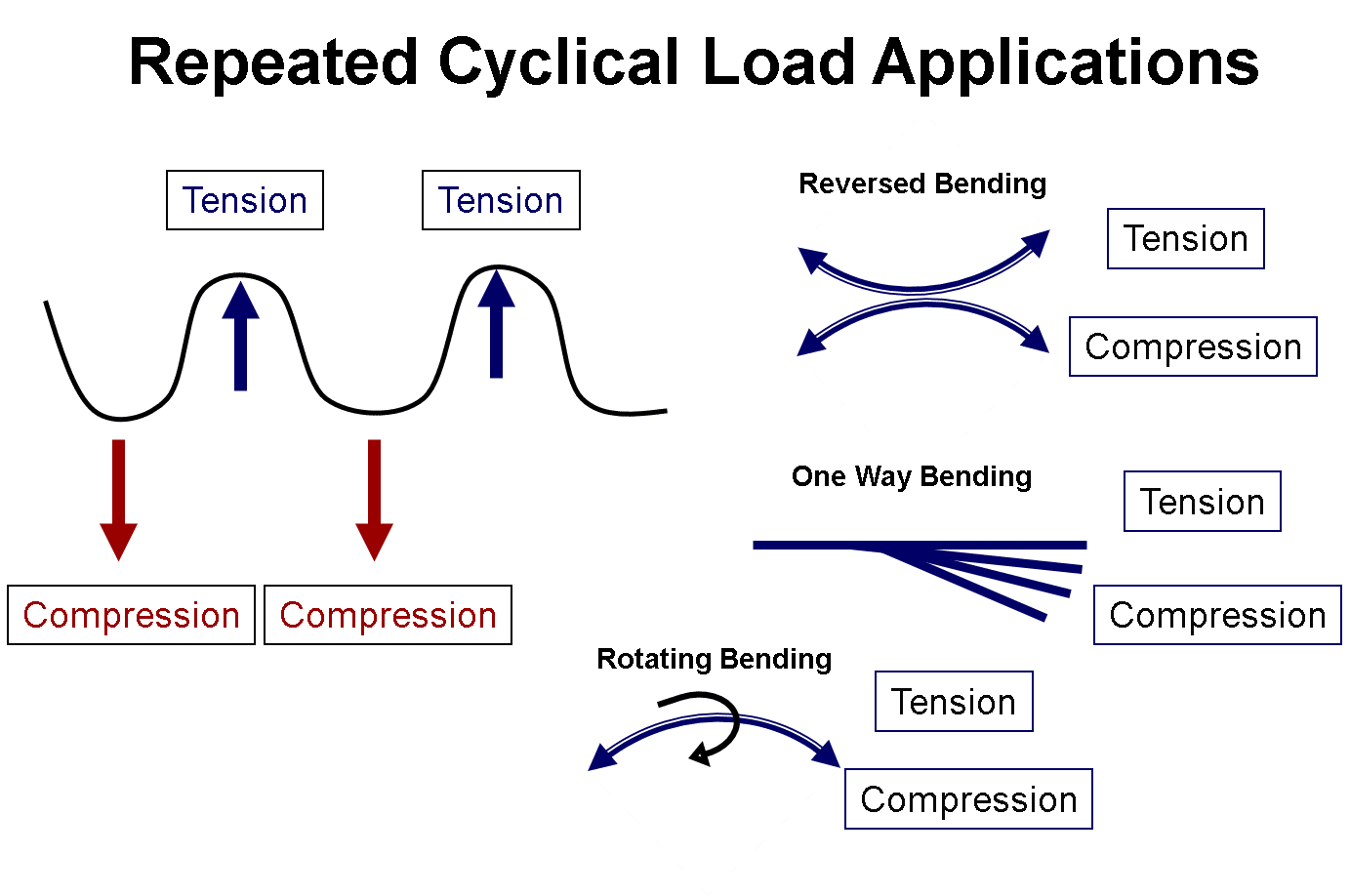

Recognizing Basic Gear Fatigue Failure Patterns

Reading Time: 3 minutes

What are Fatigue Failure Patterns? In our prior blog on Fatigue we discussed the various cyclical loading applications. Let’s review them again with this graphic. Basic Characteristics of Gear Fatigue Now let’s get a little bit more specific and discuss the basic characteristics of Gear fatigue. Some of these basics are: Let’s run through some failed parts and see if we can

A Mechanic’s Story: The Human & System’s Contribution

Reading Time: 7 minutes

Shallow Cause Analysis vs. Root Cause Analysis In this original post, A Mechanic’s Story: Basic Component Fatigue, we took a detailed journey through the physical side of a shaft failure RCA. We stopped at the physical side of that failure, parallel misalignment. However, stopping at the component level of failure does not constitute a credible and thorough RCA. Actually stopping at

The Pro’s and Con’s of Using Pre-Existing Logic in Root Cause Analysis (RCA)

Reading Time: 13 minutes

The Pro’s and Con’s of Using Pre-Existing Logic in Root Cause Analysis (RCA) By Robert J. Latino, CEO, Reliability Center, Inc. Abstract: There has been an ongoing debate for decades as to whether or not the use of pre-existing logic for conducting Root Cause Analyses helps or hinders the analysis results. Does the use of such pre-existing logic expand the thinking

Why Can’t Learning Teams (LT) & RCA Teams be Friends?

Reading Time: 7 minutes

Why Can’t Learning Teams (LT) and RCA Teams be Friends? A Little History About How I Came Across Learning Teams. A little over three years ago I was asked to speak at a conference that was entitled, Human Performance, Root Cause and Trending or HPRCT (great conference BTW and I encourage you to attend). This was a different world for me as I typically

Accepting We Could Be Part of the Problem

Reading Time: 6 minutes

Abstract: No matter where we work, we will experience failures or ‘undesirable outcomes’ of some kind. As long as we work with other humans, this will indeed be the case. These failures may surface in the form of production delays, injuries, customer complaints, missed deadlines, lost profits, legal claims and the like. In order to prevent the recurrence of any such undesirable outcome,