Root Cause Analysis Without Verification is Conventional Wisdom

Reading Time: 5 minutes

Root cause analyses are done every day all over the world. Organizations do root cause analysis because it is good business. From an explosion in an auto parts plant to the wrong prescription being given to a patient. Events such as these can have dramatic monetary, physical and psychological effects on an organization. To solve problems down to the true

Name That Failure | Part 3

Reading Time: 4 minutes

Can you identify and name this fracture pattern? How can you tell it is that fracture pattern? Where are the origin(s) of the failure on the fractured surface? How can you tell where the origin(s) are?

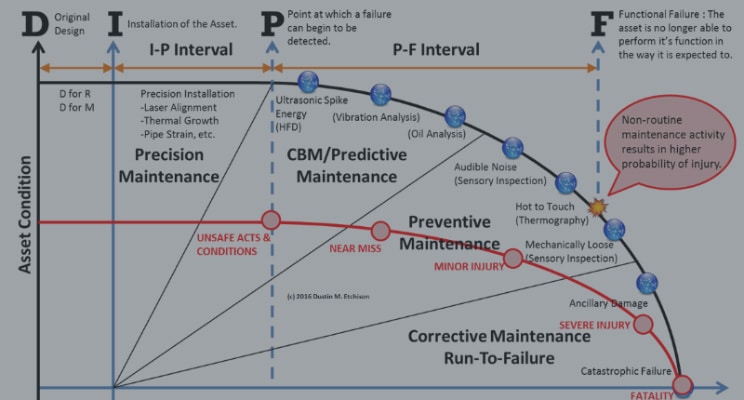

Is There Really a Direct Correlation Between Reliability & Safety?

Reading Time: 6 minutes

Safety is often directly correlated with system or component reliability. Is that really the case? Find out what the experts and their data really says.

3 Steps To Make RCAs More Impactful For Your Managers

Reading Time: 10 minutes

If managers knew what the overall power of a well supported Root Cause Analysis (RCA) effort meant for their bottom-line, they would be breaking down doors to implement the process. Unfortunately, this is often not the case, so this paper is an attempt to educate such individuals about the characteristics of an effective RCA methodology. The paper focuses on the

The Secrets of How To Be a Good Reliability Engineer

Reading Time: 8 minutes

What does it take to be a good Reliability Engineer? Learn how to better utilize RCA thinking, develop Reliability habits, and how to build a business case with your management team. To increase your impact, you need to start thinking like an owner. Read on to learn The Secrets of Successful Reliability Engineers.

Understanding the Principles of Reliability

Reading Time: 8 minutes

Understanding the Principles of Reliability Abstract: The Reliability Approach… “Something understood and practiced by engineers and highly specialized technicians,” is apt to be the first reaction of the line supervisor, “certainly not an area where I can be expected to become involved.” Although this reaction is understandable; nothing is farther from reality. Let’s explore why in this paper. Please read

What is ‘Reliability Engineering’?

Reading Time: 3 minutes

What is ‘Reliability Engineering’? I have been very involved recently with ongoing LI discussions with respected and noted experts in the Safety community, revolving around the perceptions those in Safety have of Reliability, and vice-versa. In Safety today, there are ‘new’ approaches emerging being lead by noted Safety researchers like Sidney Dekker, Erik Hollnagel and Todd Conklin. Such ‘new’ approaches

Accepting We Could Be Part of the Problem

Reading Time: 6 minutes

Abstract: No matter where we work, we will experience failures or ‘undesirable outcomes’ of some kind. As long as we work with other humans, this will indeed be the case. These failures may surface in the form of production delays, injuries, customer complaints, missed deadlines, lost profits, legal claims and the like. In order to prevent the recurrence of any such undesirable outcome,